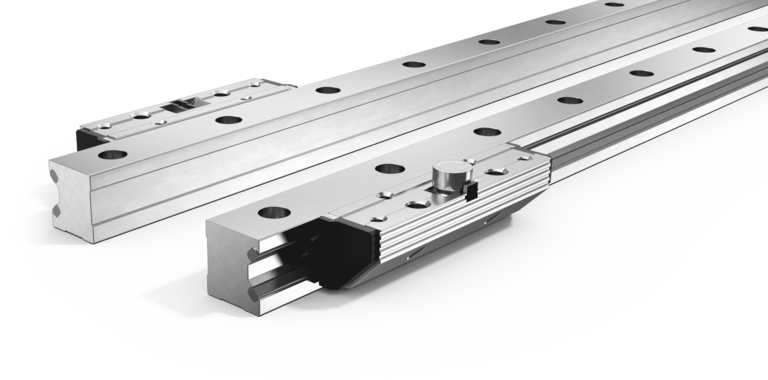

The Franke Principle for Linear Systems

Uniquely dynamic.

Uniquely individual.

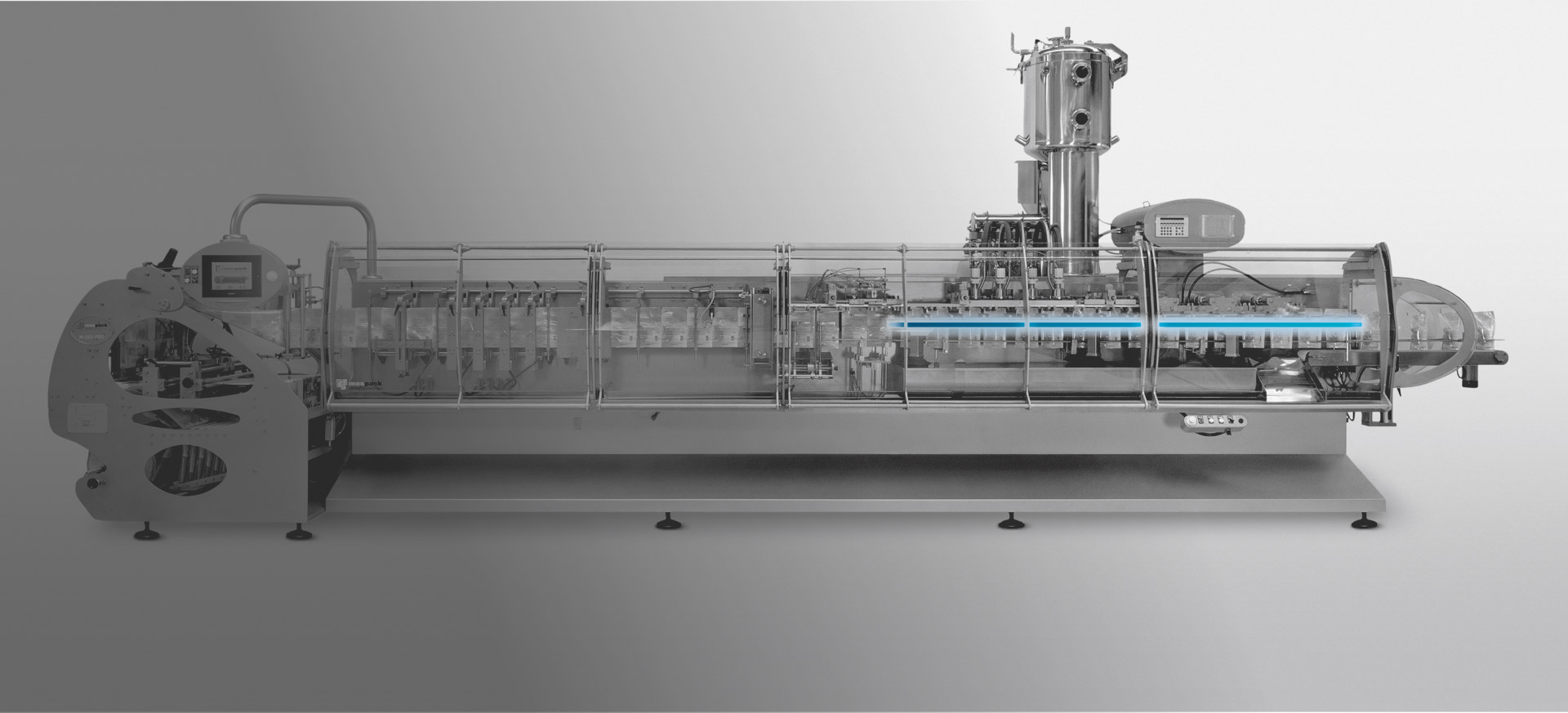

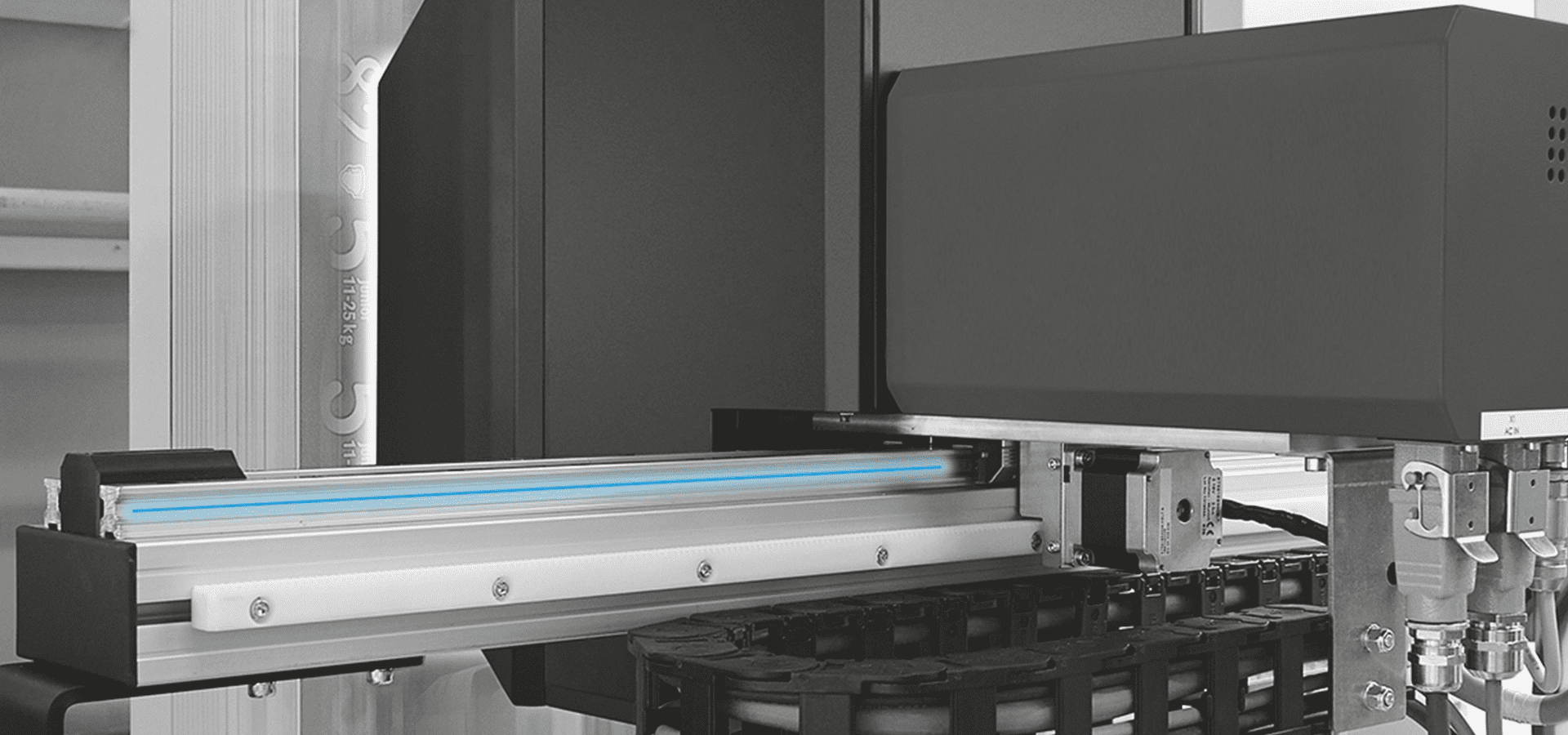

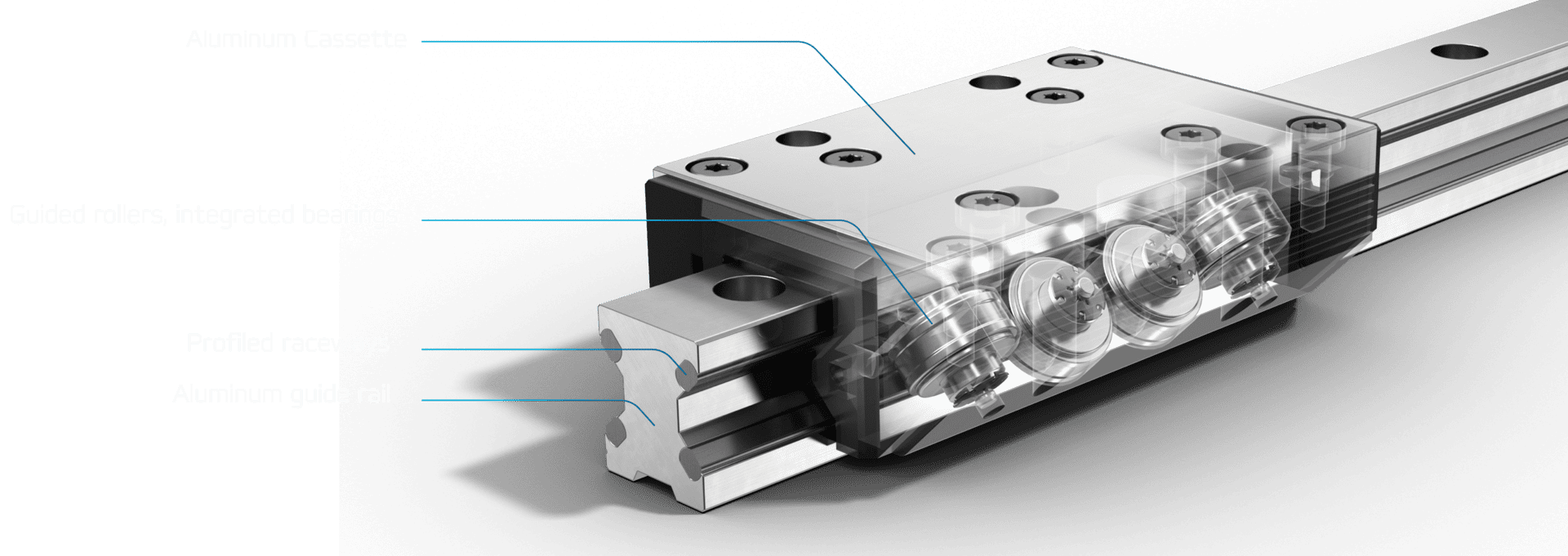

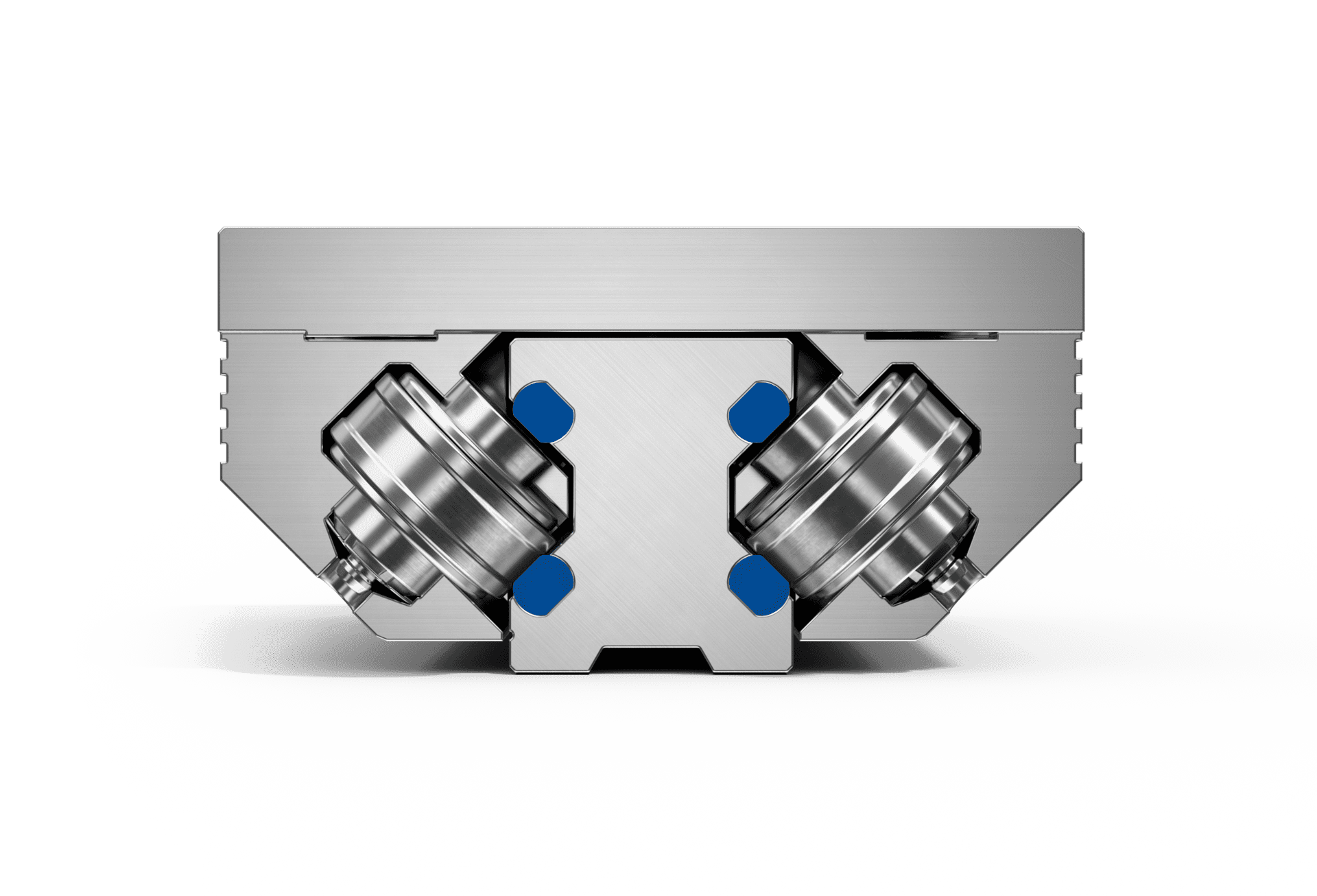

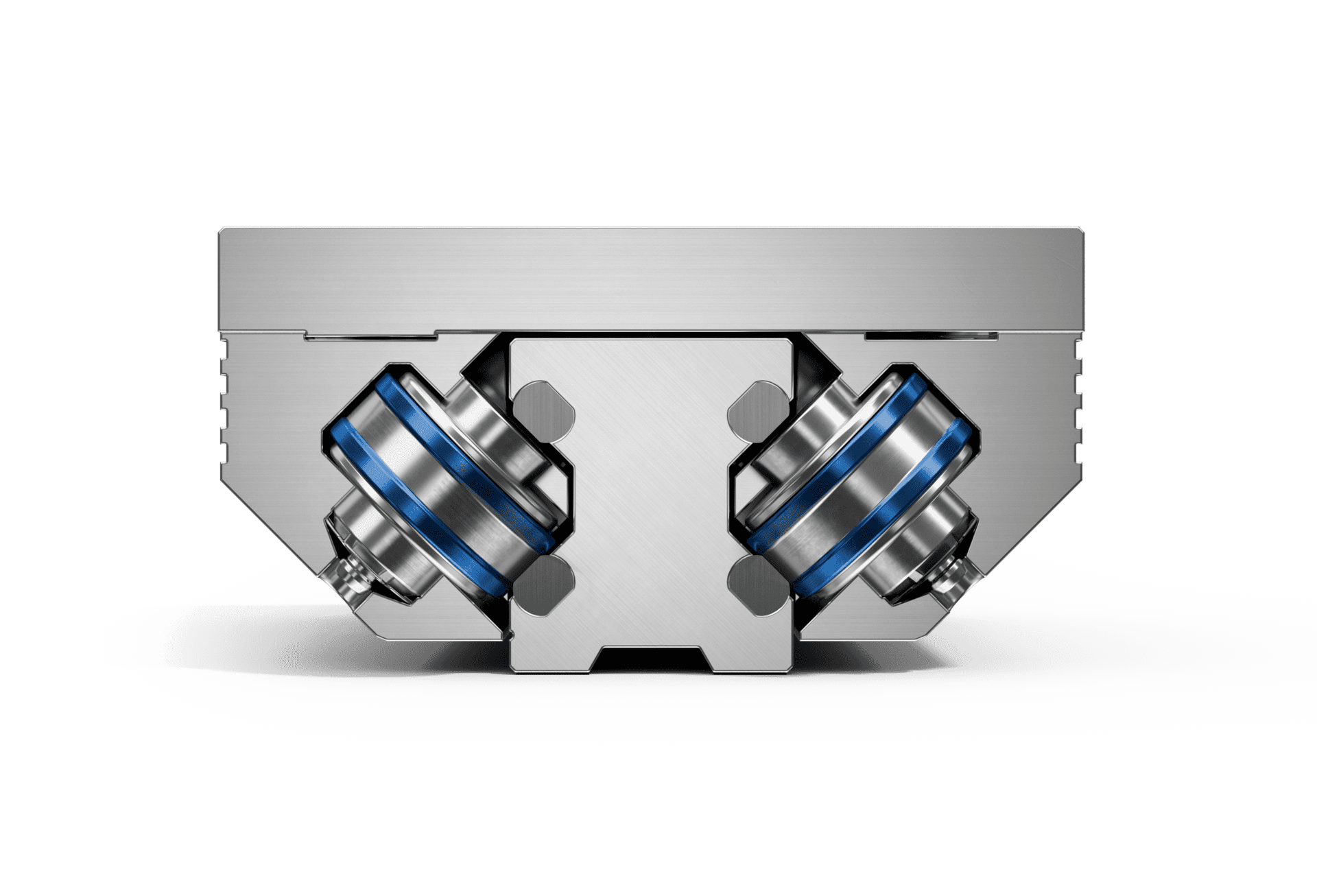

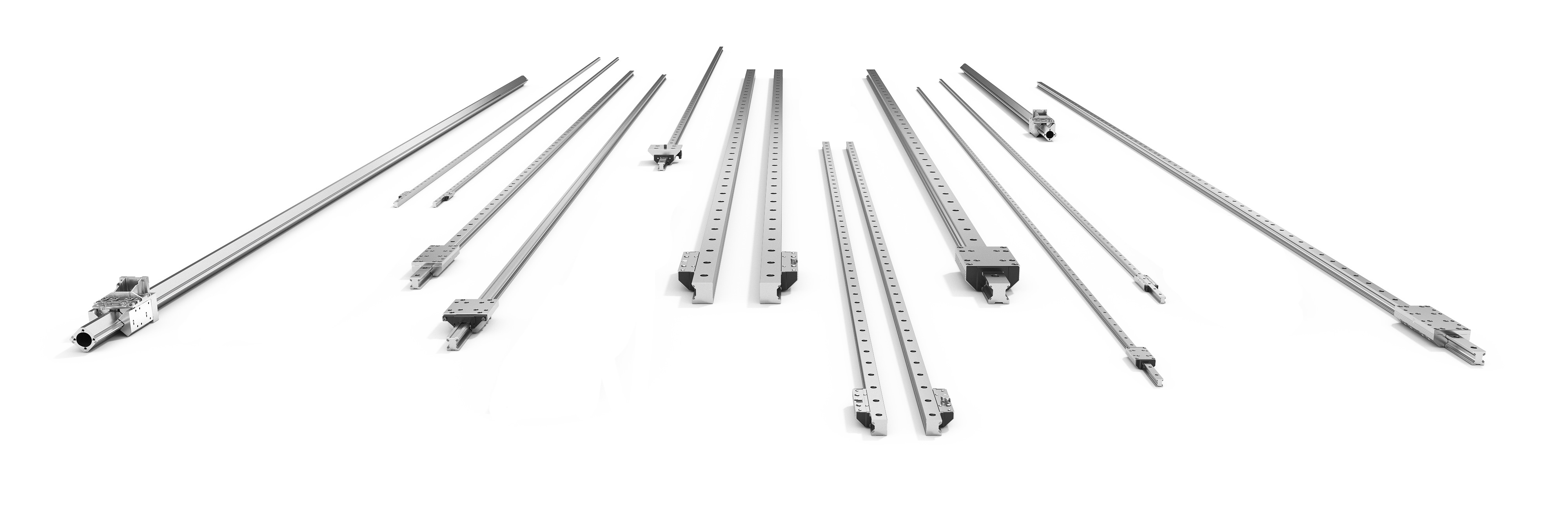

Franke linear systems transfer the ingenious principle of the wire-race bearing to linear movements. Inserted raceways ensure the load capacity on all sides. The rest of the construction can therefore be made of lightweight aluminum. Large guided rollers ensure smooth running - maintenance-free over the entire service life. Thanks to their modular design, Franke linear systems can be individually adapted to requirements.

Your solution - delivered quickly

You will probably already find the right linear system for your application in our varied standard program. Further requirements can be met individually - just ask us.

Whitepaper linear systems

Discover in our whitepaper what the special features of this technology are and how individually it fulfils every customer requirement.

Rely on maintenance-free linear systems with consistent performance in the future.

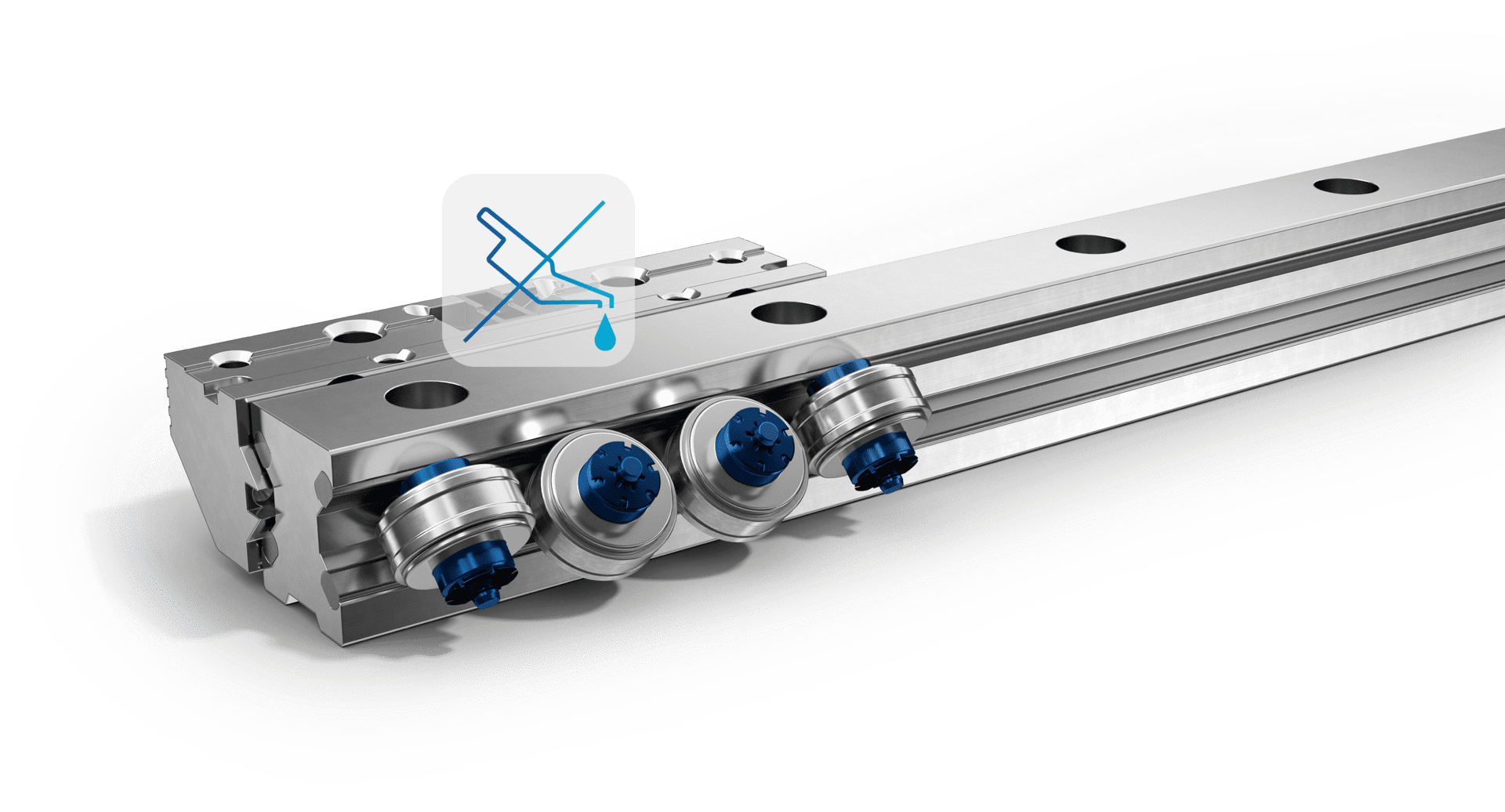

Maintenance-free - carefree

The needle or ball bearings used in the rollers are lubricated for life. This means that no maintenance is required over the long life of a Franke linear guide. For applications in the food industry we also offer lubricant-free roller bearings.

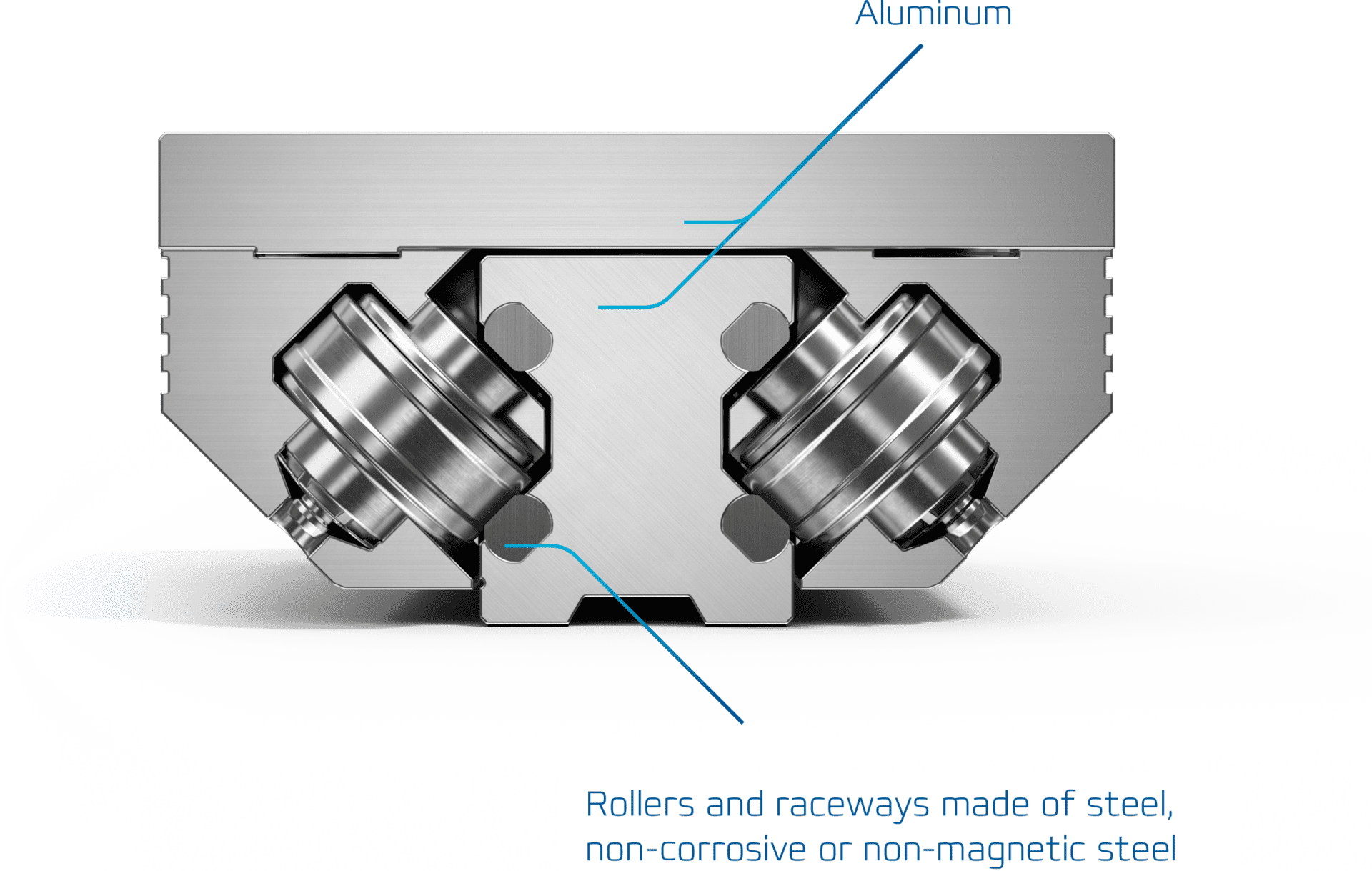

Designing homogeneously with aluminum

The main components of Franke linear systems - rails and cassettes - are made of aluminium. Franke linear systems are ideally suited for constructions made of aluminum, because the homogeneous materiality excludes temperature-related distortions.

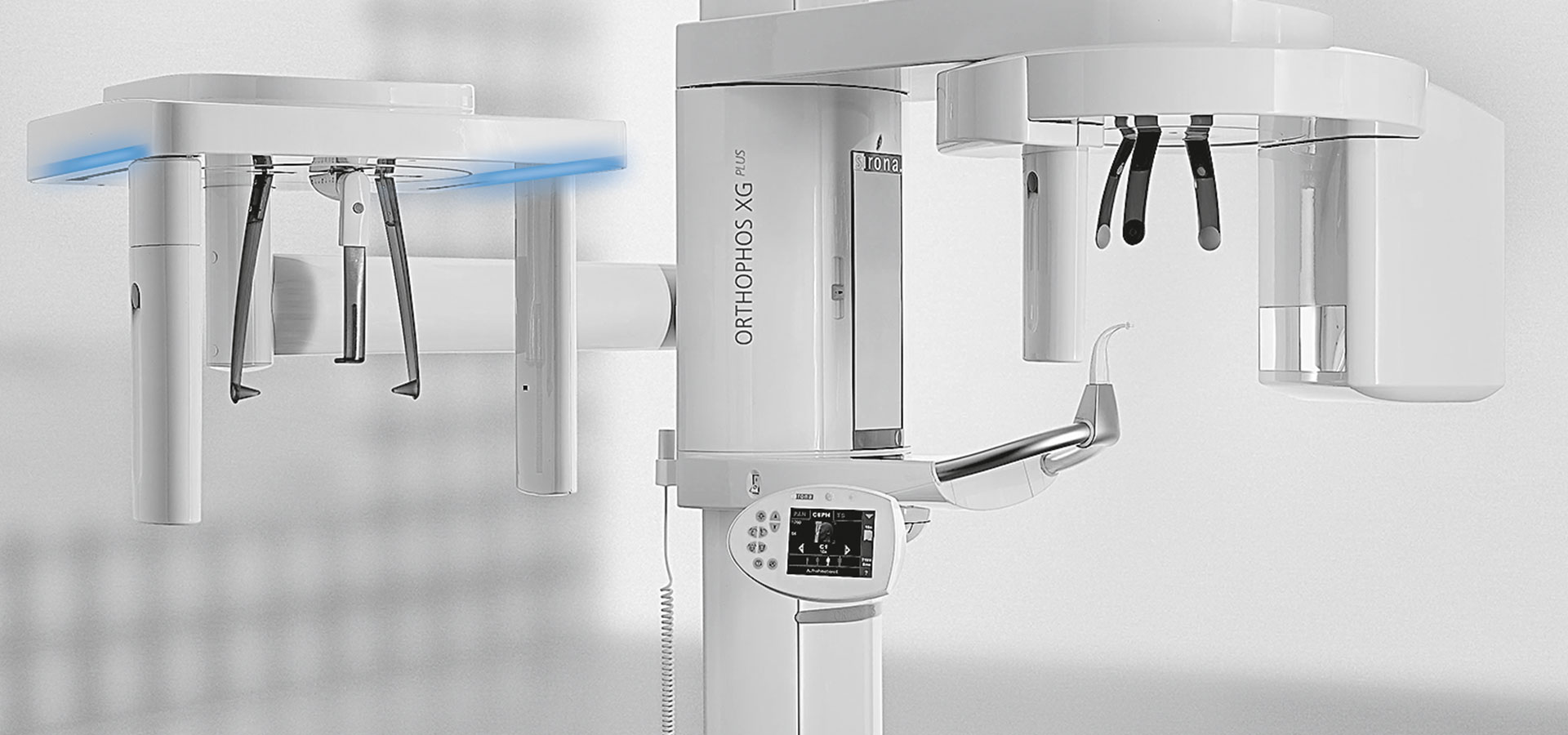

The quieter the better

Where Franke linear systems are used, you hear almost nothing from them. Only a quiet, homogeneous noise can be heard. This makes them ideally suited for noise sensitive applications. Furthermore, the whisper-quiet operation is an audible quality feature.

Highly accurate and durable

Franke's core competence lies in the high-precision manufacture and machining of wire raceways. The pursuit of precision determines every single step of our work. The result is bearing solutions with outstanding accuracy values and an excellent service life.

Patented guidance

Franke track rollers have a groove adapted to the wire tracks. This patented type of guidance prevents the rollers from sliding on their bearing pins and rubbing against the housing. The advantage: a lower friction, more controlled movement.

Let us advise you!

From a Franke expert via video-chat, at your site or at our premises.