Location development 2025: Franke continues to grow!

Since the company was founded in 1949, Franke has continued to develop. New production facilities are regularly built in the immediate vicinity of the headquarters in Obere Bahnstraße. They are a visible expression of the continuous growth - and a strong commitment to the Aalen location. The latest expansion: Plant 6 for the production of high-end rolling bearings

The new building will go into operation at the beginning of 2025 and will allow manufacturing processes to be combined into efficient production units. In the further course of the project, around 35 production-related office workstations will be created on an intermediate level in Plant 6 to consolidate the successful matrix organization. The technical building equipment and the targeted installation of PV systems over the years will make a significant contribution to Franke being climate-neutral as early as 2025.

Franke is constantly building new production facilities in the immediate vicinity of its headquarters. They are a visible expression of continuous growth - and a strong commitment to the Aalen site. Designing the expansions to be climate-friendly and operating sustainably is a matter of course for us and is documented in our sustainability report.

- Plant 1,4,5: Rolling bearings for industrial applications

- Plant 2: Technicum, training, equipment & plant construction, research & development

- Plant 3: Linear guides

- Plant 6: High-end bearings for computer tomographs, baggage scanners, etc.

- Head office / meeting point: Customer center, events

The new Plant 6 in figures:

- 28,000m³ excavation

- Production area 4.927m²

- Total area 7.815m²

- KFW 40 standard

- Heating via 2 reversible heat pumps (heating & cooling) as well as compressed air heat recovery and gas peak load boiler

- The waste heat is stored in a 5000 l buffer tank, the main return flow is routed via the buffer tank if required.

- 3 ventilation systems for fresh air: AHU 1 for production with adiabatic evaporative cooling in summer. AHU 2 for offices, social rooms, etc. with adiabatic evaporative cooling in summer, AHU 3 for the kitchen

- Lighting complete with LED lights. l PV system output: 451.53 kWp

Expansion of capacity

New machines increase capacity

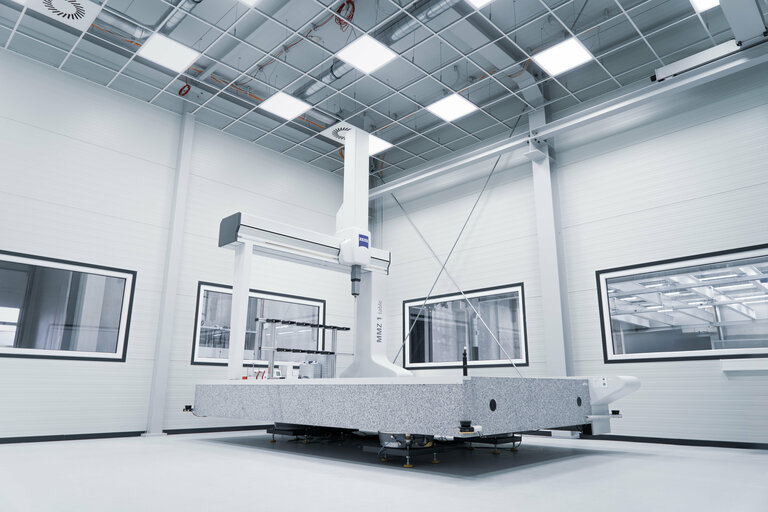

With the acquisition of an additional machining center and a state-of-the-art coordinate measuring machine, we are significantly strengthening our production capacities in Plant 6. The machining center is equipped with a 12-pallet changer and enables us to manufacture efficiently and flexibly. It is complemented by the new coordinate measuring machine, which has an impressive measuring range of 2x2 meters and can also precisely inspect large workpieces. These investments are an important step towards meeting the increasing demands of our customers and further optimizing the quality of our products.

Moving into the new Plant 6

The relocations will be divided into various phases and are expected to take up a large part of the 2025 financial year. The relocation of high-end warehouse production should be completed by the end of April and the restructuring of industrial warehouse production by the end of October. We will then tackle all subsequent changes at the beginning of 2026. A relocation project of this magnitude harbors opportunities and risks. Risks can arise due to weather conditions, for example. Opportunities arise when things go faster than planned - in this case, follow-up activities can also be brought forward. We endeavor to meet our customers' needs as best we can, even during the relocation phase.