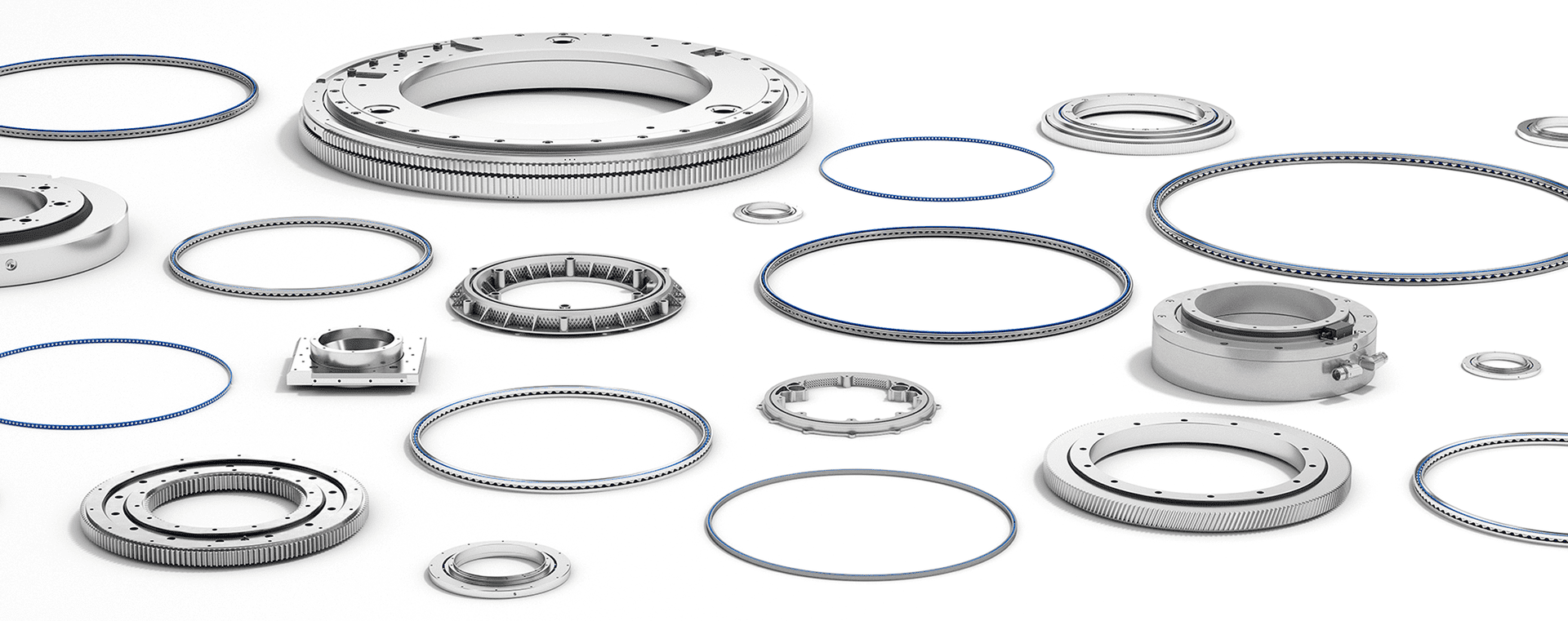

The Franke-Principle of Bearings

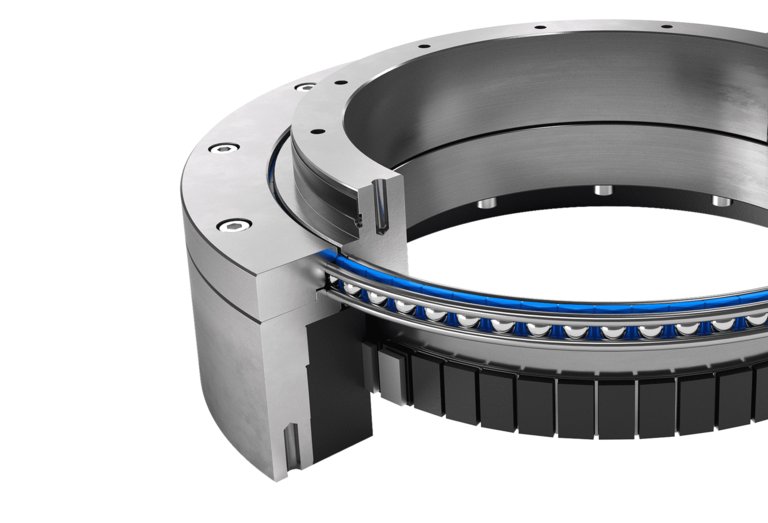

Four wires for better design

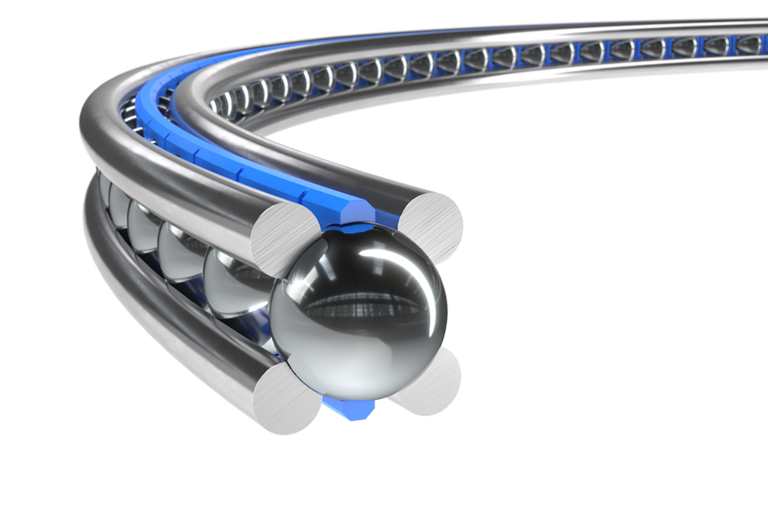

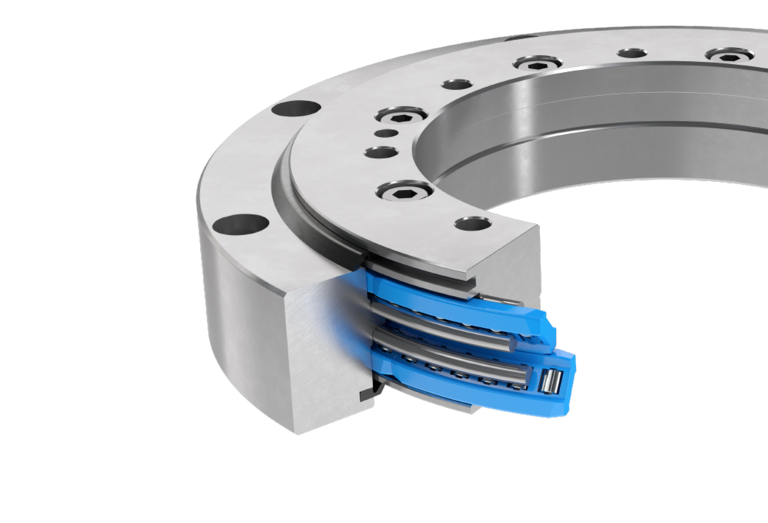

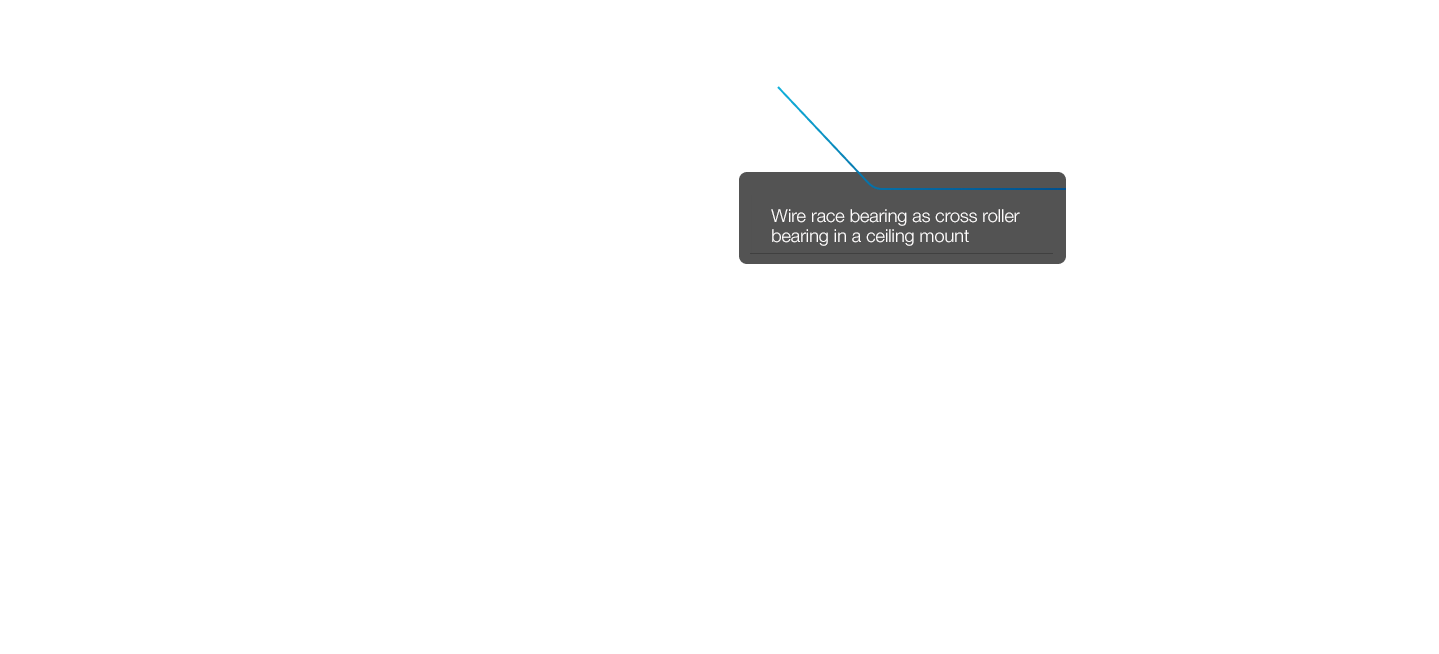

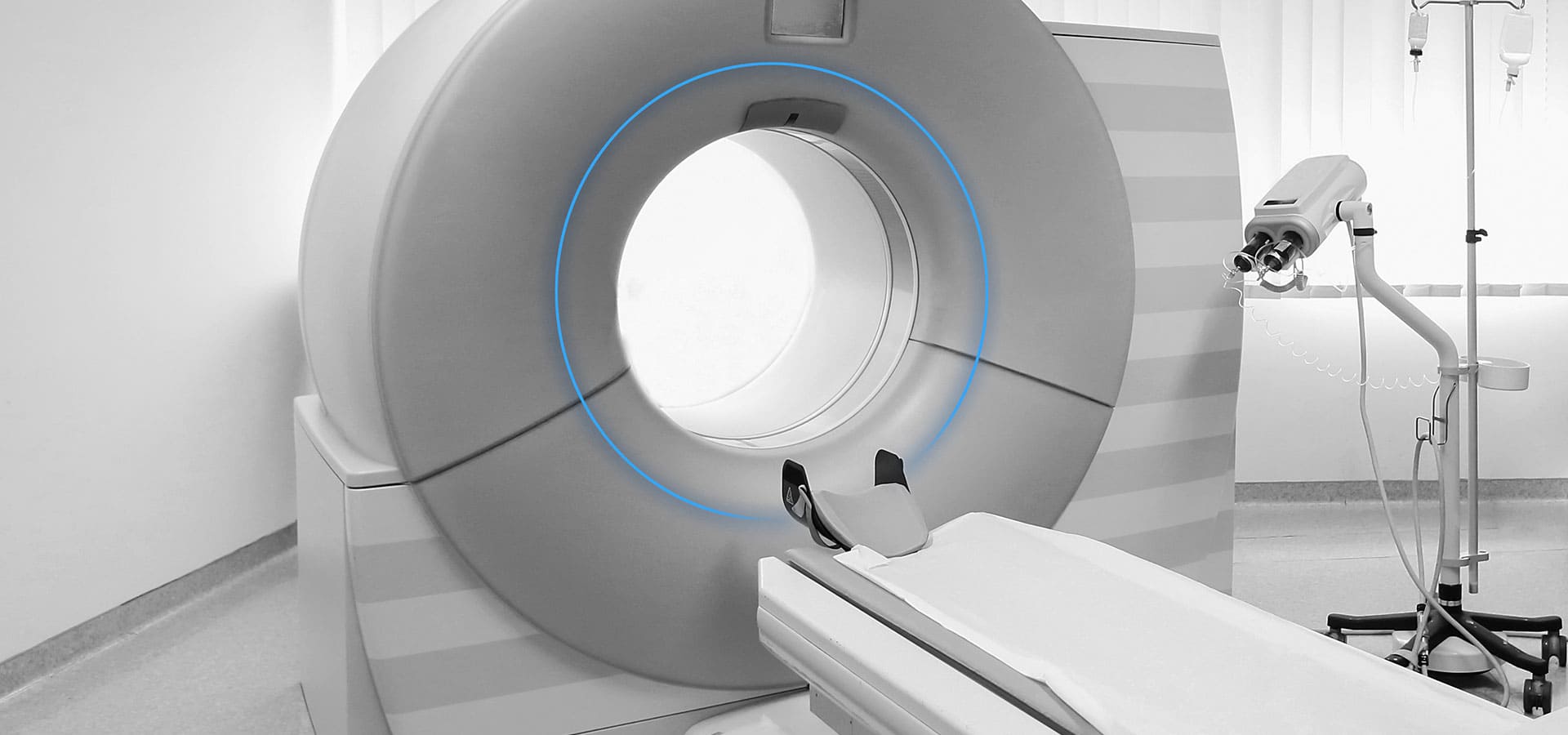

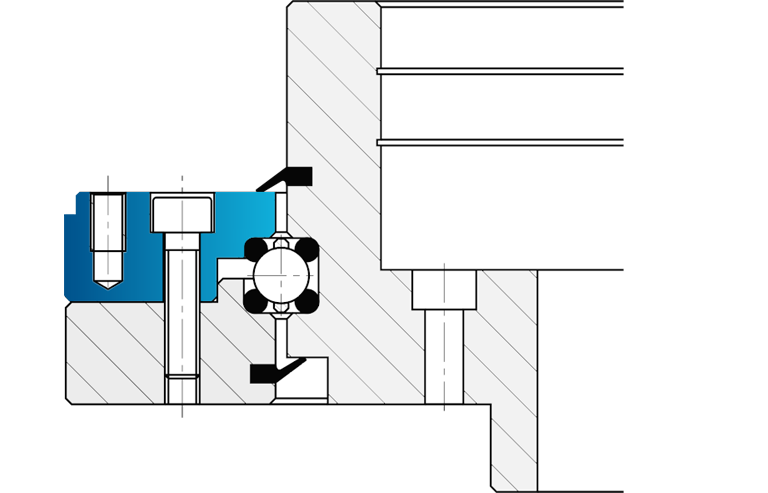

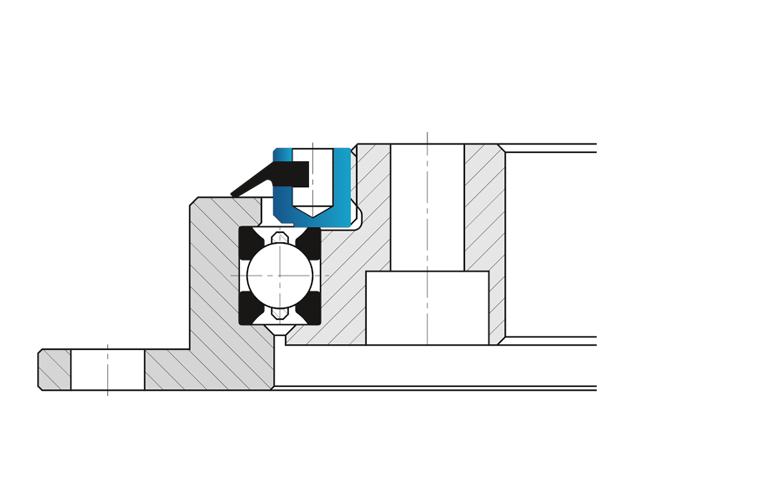

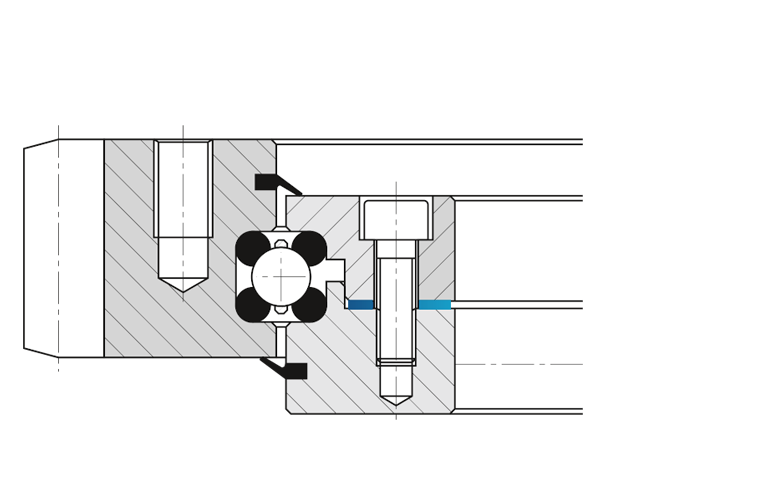

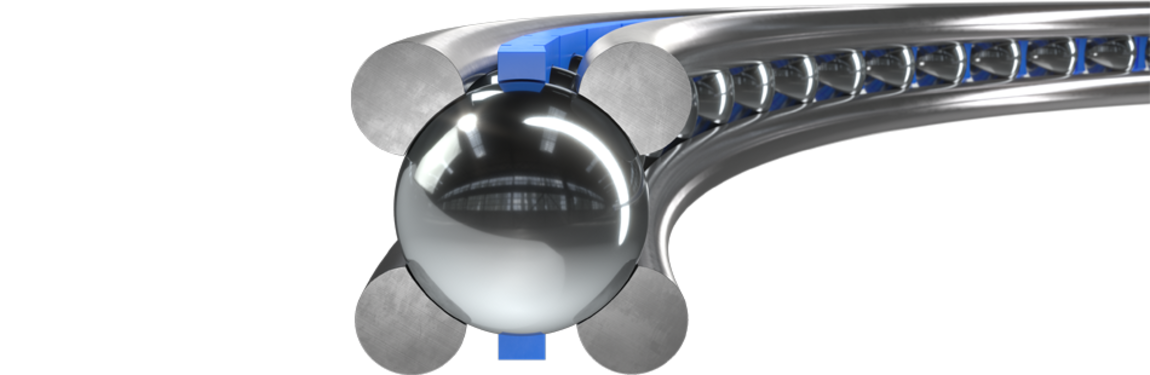

The decisive difference between an ordinary ball bearing and a Franke wire race bearing is in the raceways. In a wire race bearing, the rolling elements do not roll on solid housing rings, but on high performance wires. The flexibility of this principle makes it possible to design more freely and simply, in order to develop better products.

It couldn't be

easier or more compact

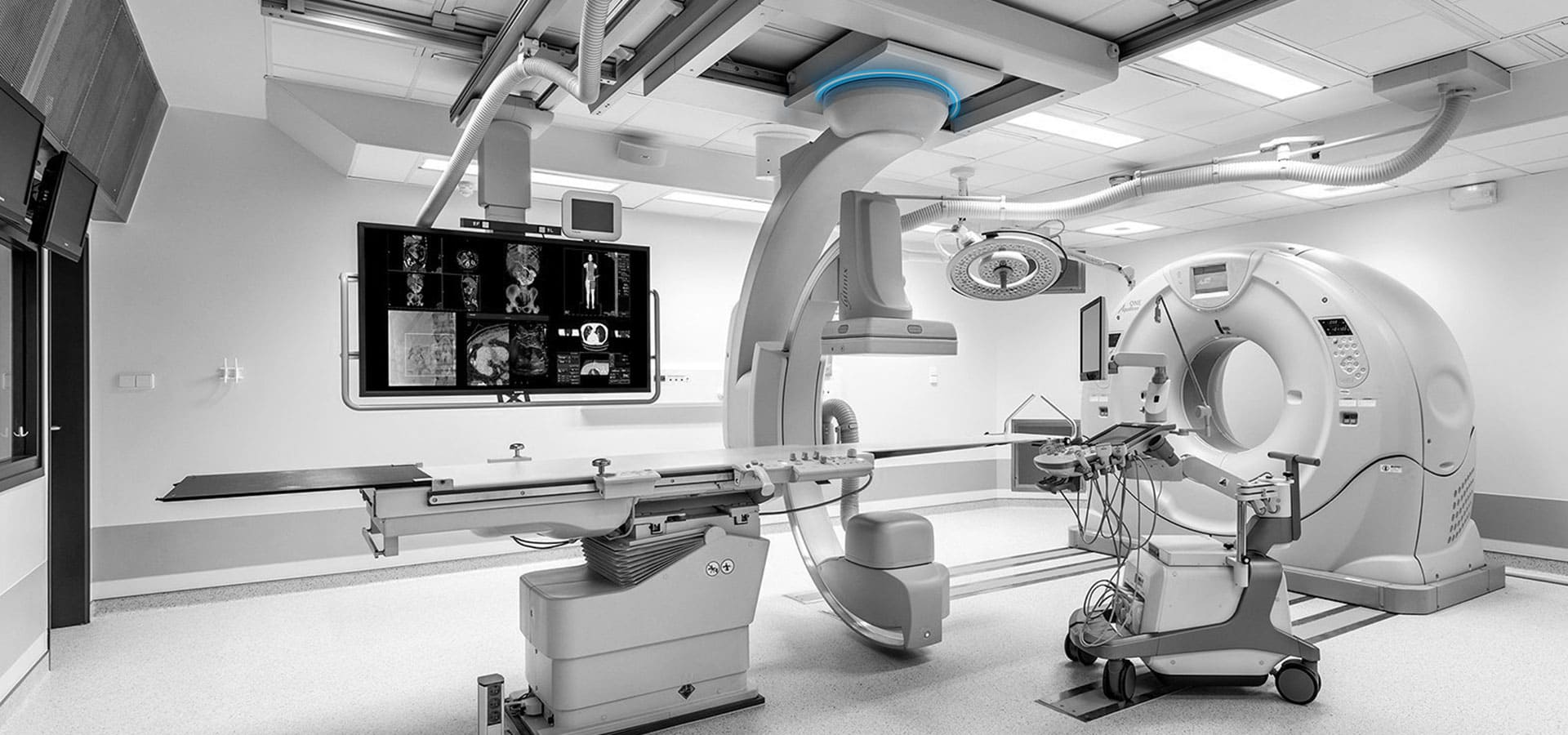

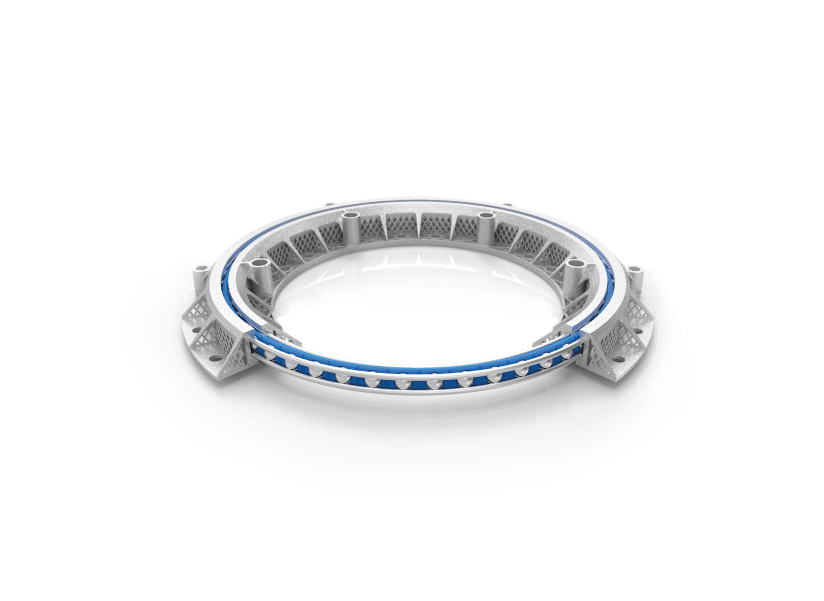

In a wire race bearing, highly resilient bearing rings made of wire assume the function of the bearing arrangement. This saves weight and space. The free choice of material and the free design of the enclosing structure also allow the weight of the overall product to be reduced considerably.

Runs precisely.

And runs precisely.

And runs precisely.

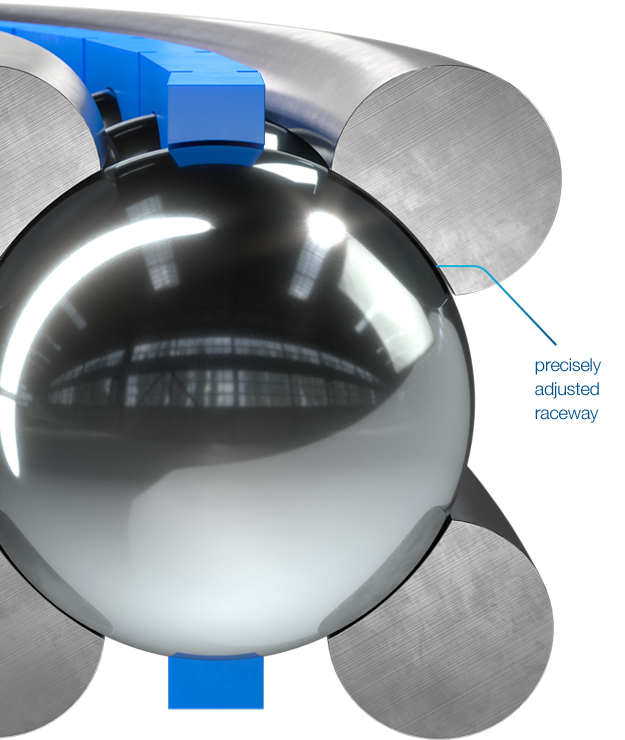

In wire race bearings, the raceways of the rolling elements are precisely matched to the diameter of the rolling elements. This ensures optimum functional characteristics and guarantees both, precise running and a long operating life.

Shock and impact elastic

The races of Franke wire race bearings are made of hardened spring steel. Shocks and vibrations are absorbed by them. The result: a high resistance against such disturbing influences.

Compensates deformations

Slight deformations of the enclosing structures, for example due to temperature changes, are compensated by the flexible Franke bearing element. Where other roller bearings fail, the Franke bearing continues to roll.

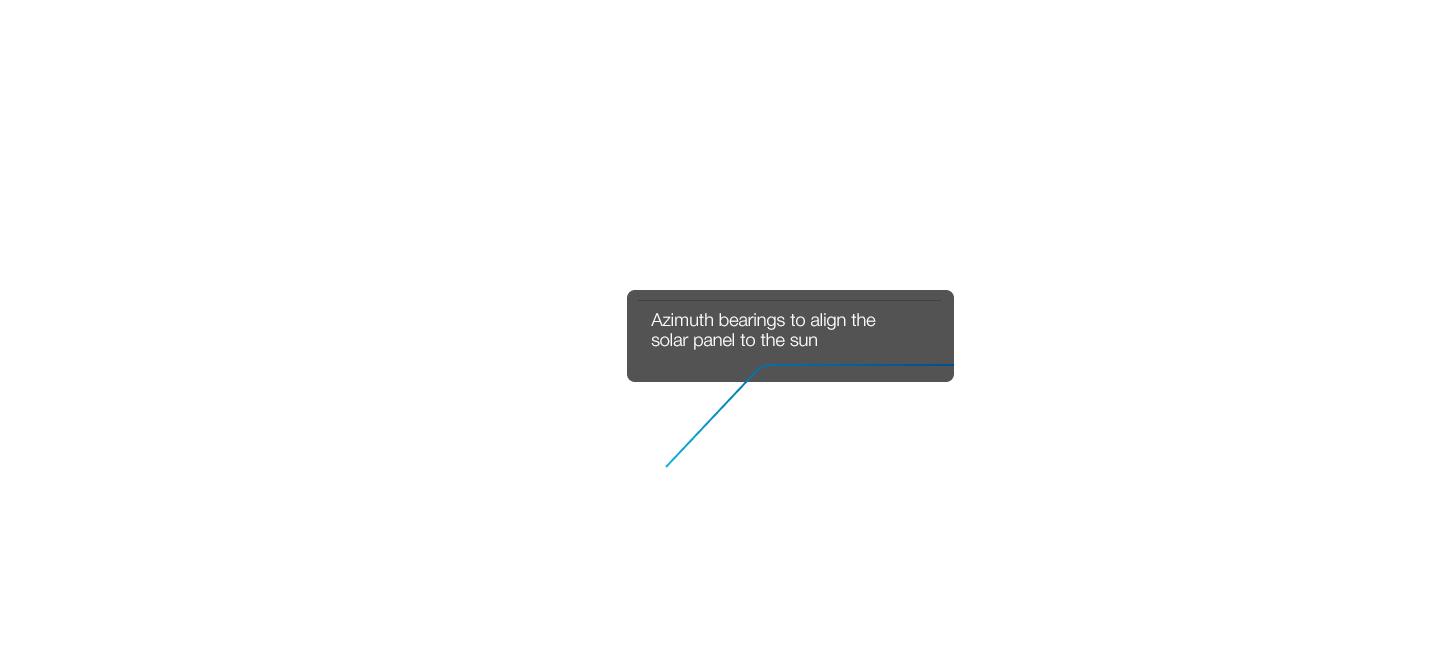

No bearing play. Adjustable rotational resistance.

Does your application focus on dynamics or precision? Or does a good compromise have to be found? The rotational resistance of a wire race bearing is adjustable. Suitable for each application. At any time.

From the idea to your bearing solution - we are always at your side

- Comprehensive consulting

- Presentation of the Franke system - at your place or ours

- Supply of sample parts

- Individual development

- Prototyping and testing

- Assembly training

- Maintenance services, e.g. retreading of bearing assemblies

Let us advise you!

From a Franke expert via video-chat, at your site or at our premises.