Customers discover the Franke principle

Franke wire race bearings and linear systems adapt to the application. Innovative solutions for rotary or linear movement are created in close cooperation with our customers. Our customer stories tell about it.

26.06.2024 - Automatisation

Automated guided vehicles from the global production optimiser

Always thinking one step ahead and offering flexibility - that is the credo of FFT, a leading global provider of automated manufacturing solutions. To achieve this, the plant manufacturer relies on collaboration between humans and robots and on digital networking.

09.10.2023 - Mechanical Engineering

Innovative winding technology for the ultimate electric car

Schaeffler ELMOTEC STATOMAT stator winding machines are used to manufacture electric motors for the luxury and performance electric car industry. Schaeffler's innovative ELMOTEC STATOMAT technology makes it possible to tightly wind the copper coils to maximum performance and efficiency. In order to achieve the required precision, the design specialist from Schaeffler turned to Franke for the perfect bearing solution.

17.07.2023 - Automation

The best all-round program for flat glass processing

LiSEC from Austria is the world leader in flat glass processing. LiSEC found the perfect solution for their highly skilled machines by utilizing Franke’s linear guides. During operation, the machine components are exposed to an abrasive mixture of cleaning water and glass dust.

24.10.2022 - Mechanical Engineering

Precise cutting on a grand scale

The Aachen-based family business Fecken-Kirfel has been in existence for over 150 years. And for over 100 years it has been perfecting solutions for efficient cutting on an industrial scale. Fecken-Kirfel is a world leader with its cutting machines. Lightweight Franke linear guides guide the bandknifes evenly and precisely through the material.

18.07.2022 - Mechanical Engineering

Mespack - masters of flexible packaging

The Spanish packaging machine manufacturer Mespack is a specialist for flexible packaging. Compared to rigid packaging, this not only saves costs and transport volumes, but also protects the environment by using fewer resources. Mespack uses linear guides from Franke in many of its machines for flexible packaging.

31.05.2022 - Automation

Making lifting easier: with handling systems from Sachs-Products

Easy operation and good design: The young company Sachs Products attaches particular importance to these properties in its handling systems. In its Manipulators Mantis and Vertis, Sachs Products uses bearing assemblies from Franke. Their smooth running, their small installation space combined with high load capacity and their low weight are decisive benefits for Sachs Products.

23.02.2022 - Mechanical Engineering

How do you digitize a library?

Scanners are commonplace technology these days. However, when it comes to scanning entire books, commercially available devices quickly reach their limits. The Swiss company 4DigitalBooks - ASSY SA manufactures scanning robots that efficiently and gently digitize entire libraries. In its market-leading fully or semi-automatic book scanners, 4DigitalBooks has been using linear guides from Franke for 20 years.

20.12.2021 - Mechanical Engineering

100 kilometres of fibre on a bobbin

The SAHM company from Eschwege is the global technology leader for winding machines for technical yarns, fibres and tapes. Bobbin weights of up to 500 kilograms can be perfectly wound with SAHM winding machines. For the machine types with automatic tube change, SAHM uses slim bearings and linear guides from Franke.

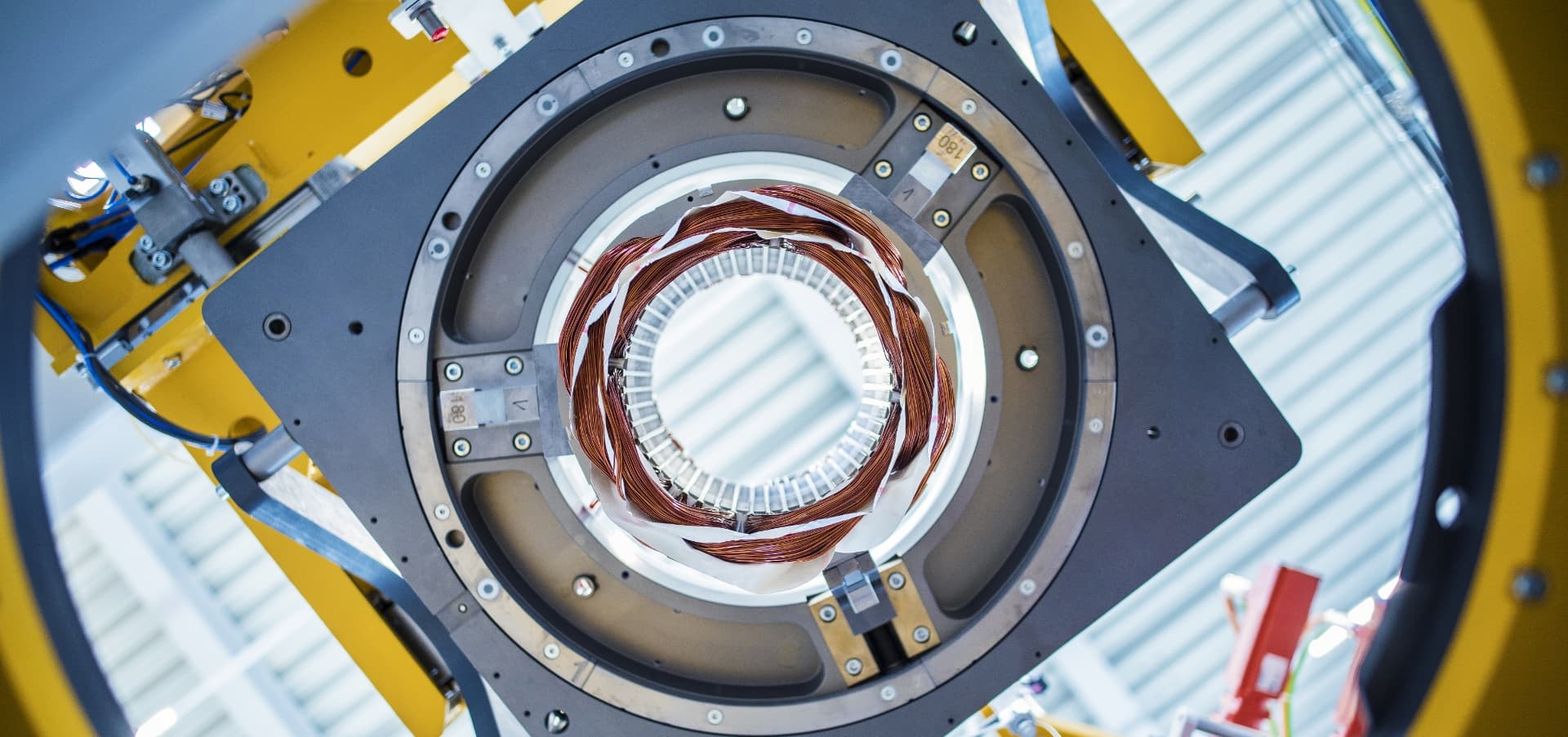

13.08.2021 - Mechanical Engineering

Risomat accelerates electrification - with the help of Franke wire race bearings

Whether in an electric toothbrush, in an e-car or in the generator of an emergency power unit - electric motors of all different sizes move our world and their number is constantly growing. With the production systems of Franke's customer Risomat, electric motors and generators can be manufactured in a highly automated way. Risomat uses specific wire race bearings from Franke for its special machines.

25.06.2021 - Mechanical Engineering

Franke solves challenging rotation task for vegetable spiral cutters from company Kronen

A challenge becomes a success story: After previously working on a solution with several suppliers, Kronen GmbH finally found the partner in Franke who mastered a difficult rotation task with a sophisticated bearing assembly.

25.05.2021 - Mechanical Engineering

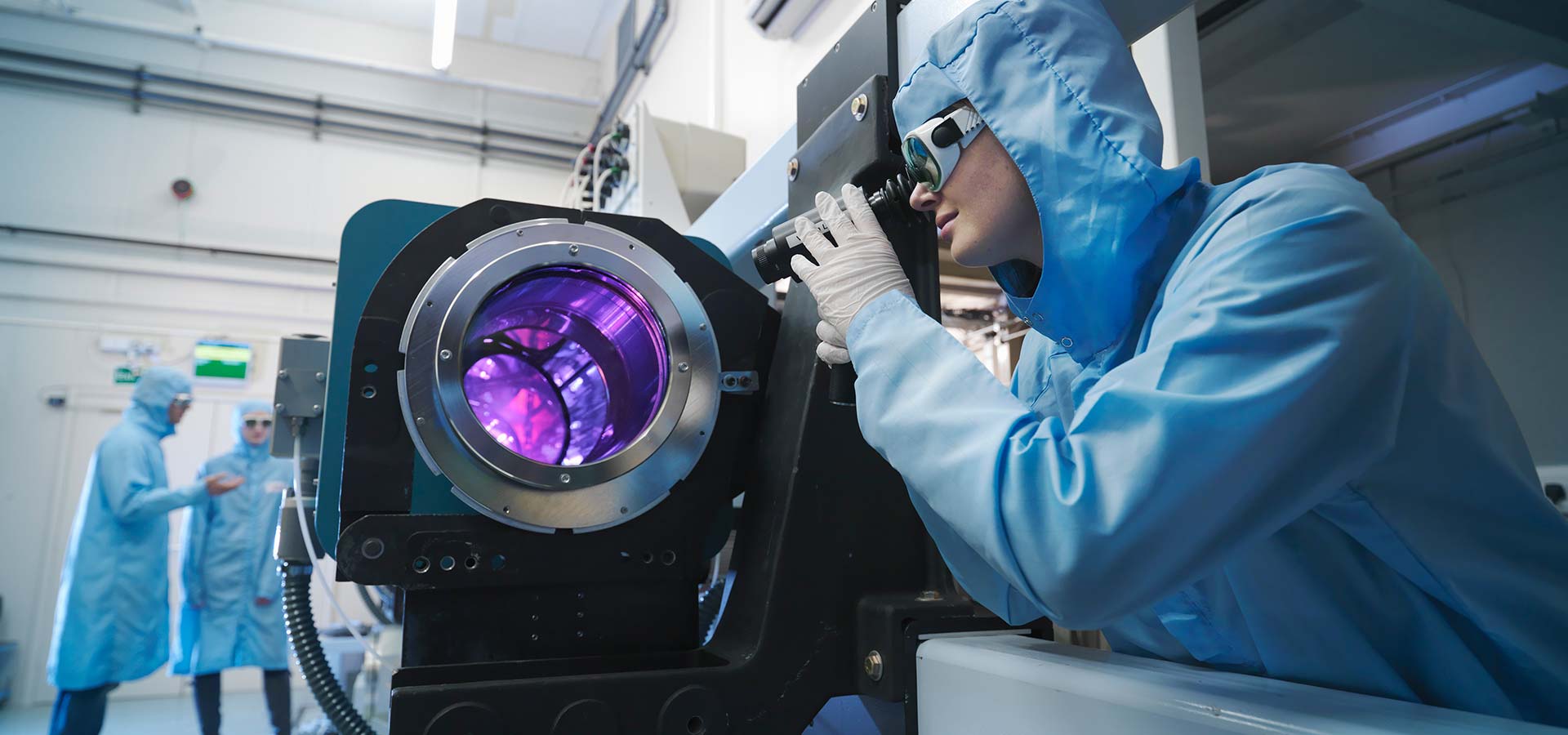

The great freedom of tube processing - with laser tube cutting machines from Trumpf

"Pipes choose Trumpf" is the title of an advertising brochure for Trumpf laser pipe cutting machines. The Swabian flagship company is a global leader in laser processing. Customer-specific bearing assemblies from Franke are used in the chucks of its fully automatic cutting artists.

11.04.2021 - Mechanical Engineering

XXL-Franke-Torque Bearing guides laser at new display repair machine

A South Korean OLED display manufacturer has developed an innovative machine to correct unavoidable errors in display production more quickly. Franke built an exceptionally large bespoke torque drive for the machine with one meter diameter.

06.05.2020 - Medical Technology

Mill-turn technology from DMG MORI for CT scanners

Franke GmbH meets the challenge of the soaring demand for system components for medical equipment such as CT scanners during the spread of the COVID-19 virus with the aid of DMG MORI machining centers.