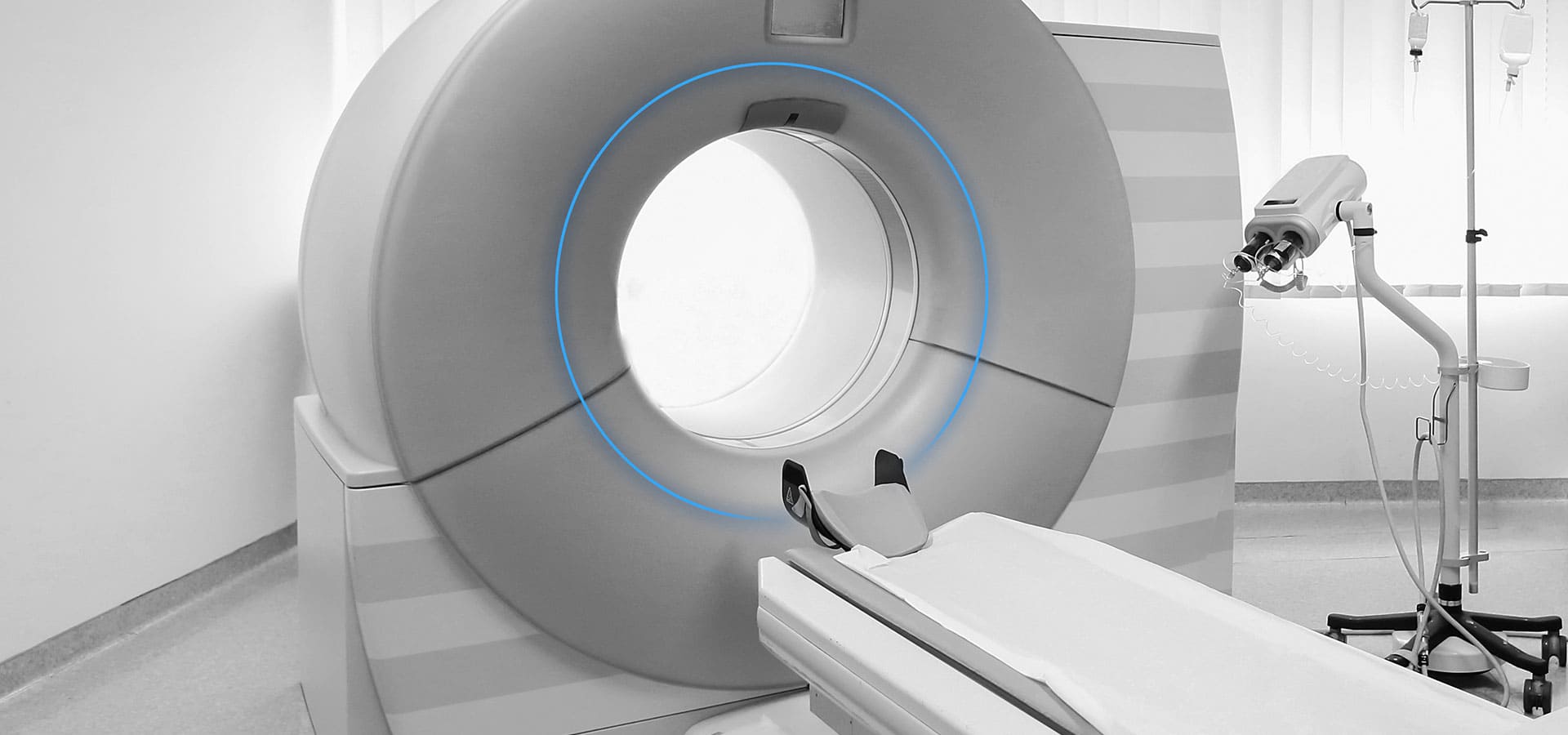

Application example Computer tomograph

Requirements

The main bearing of the computer tomograph is partly responsible for ensuring that accurate images are delivered. Even at high speeds, it must run quietly and with low vibration. Exact radial and axial runout must be guaranteed.

Solution

A customer specific patented Franke whisper bearing with elastomer. In addition to the high running smoothness, Franke CT bearings have an optimal rotational resistance. The radial and axial runout is a few hundredths of a millimetre, depending on the design and diameter. All Franke CT bearings are adjustable according to customer requirements. The internal elasticity makes the bearing extremely robust even under the toughest operating conditions.

Bearing solution used

Advantages

Extremely quiet running at up to 300 rpm. Noise is dampened by the elastomer (60 dBA). The bearing has a low rotational resistance (< 20 Nm) and electrical insulation between the inner and outer ring. Loads of more than 1,000 kg are possible.

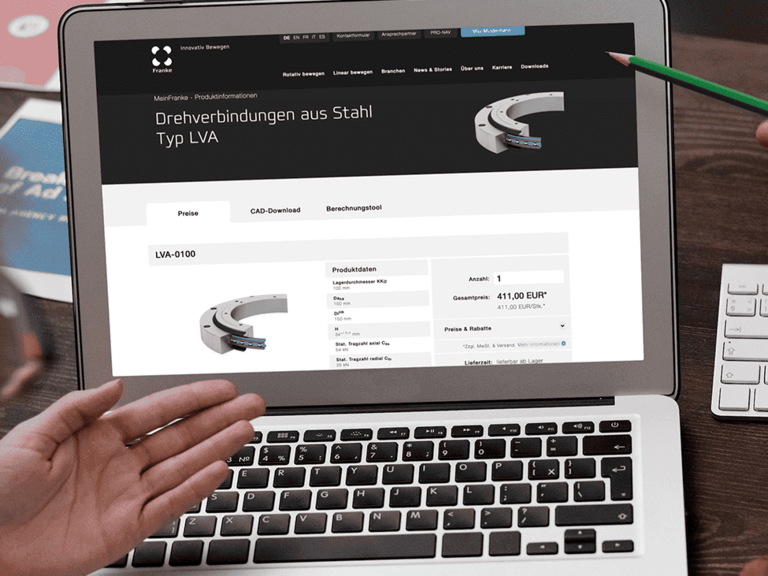

More about the products

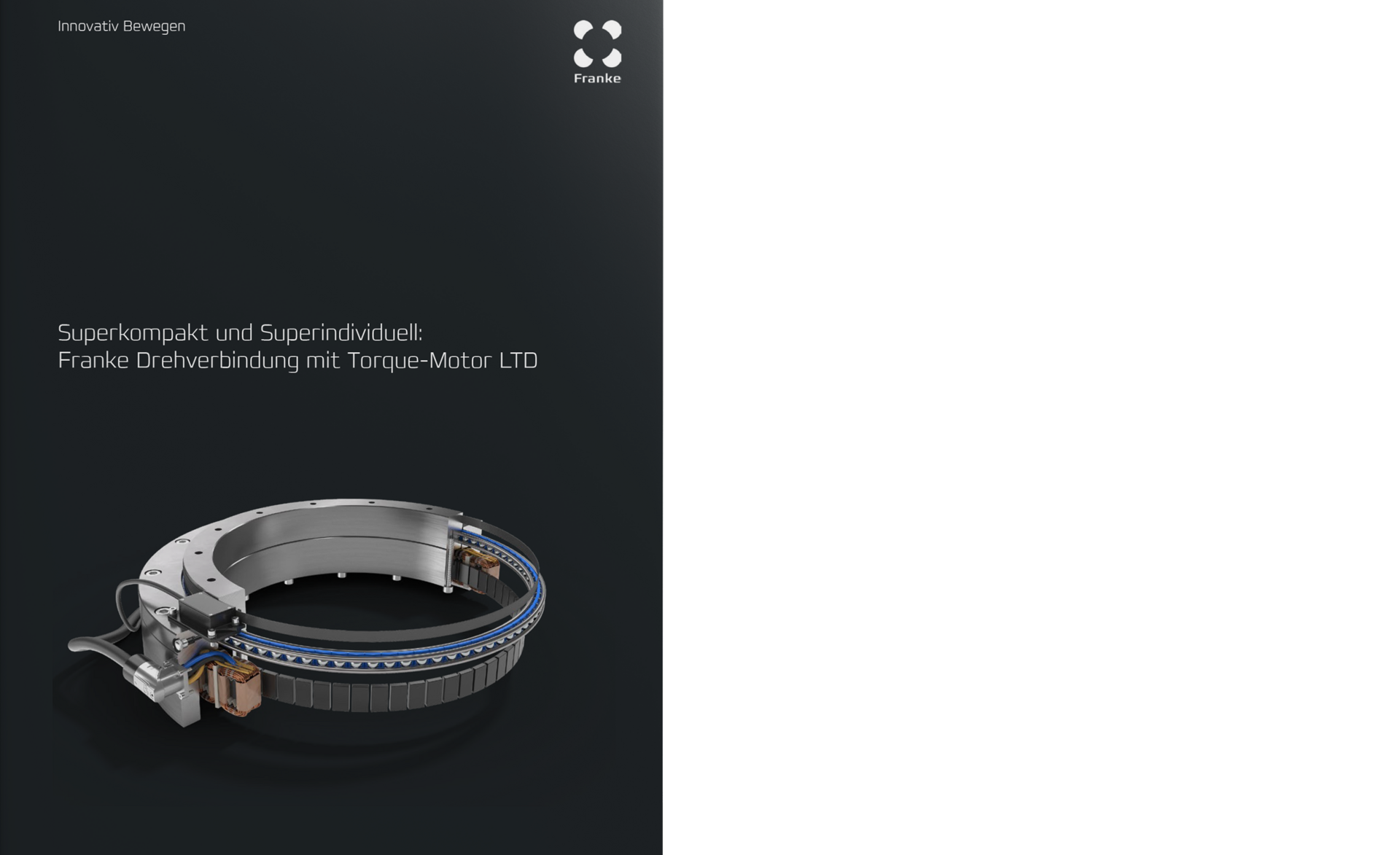

Whitepaper slewing ring with torque drive

Find out more about slewing rings with integrated torque motor and why it is superior to other drive types in almost every respect.

In future, dispense with components such as gearboxes and drive pinions.

NEW: Revolutionary rolling bearing technology for vertical applications:

Bearing assembly with segmented direct drive sets new standards in terms of performance and service life

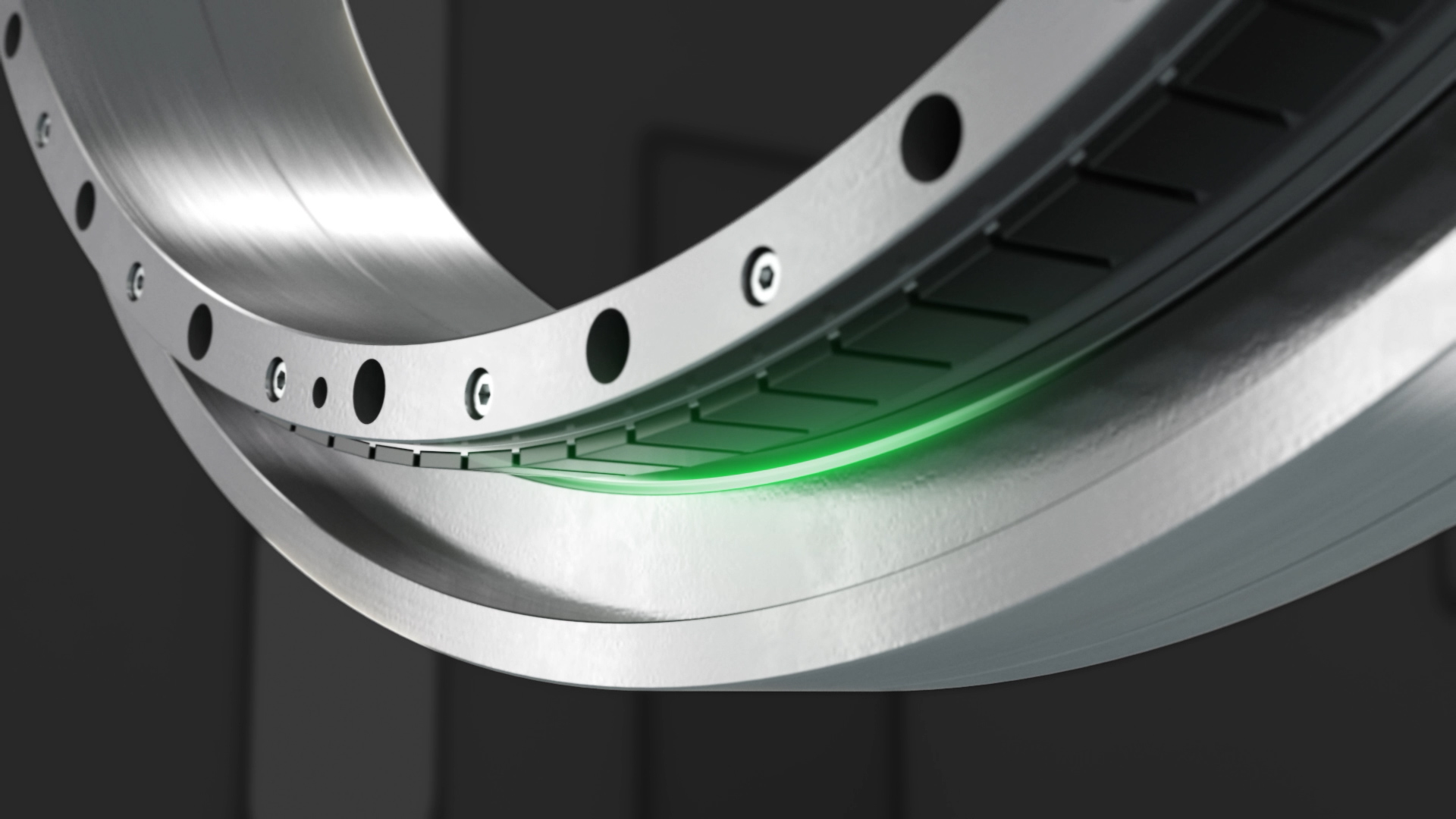

In a ground-breaking technological development, Franke presents itself as a pioneer in the field of advanced bearing technologies with the bearing assembly with segment motor. This innovative solution integrates a wire race bearing with a motorised direct drive that overcomes the traditional limits of vertical bearing applications.

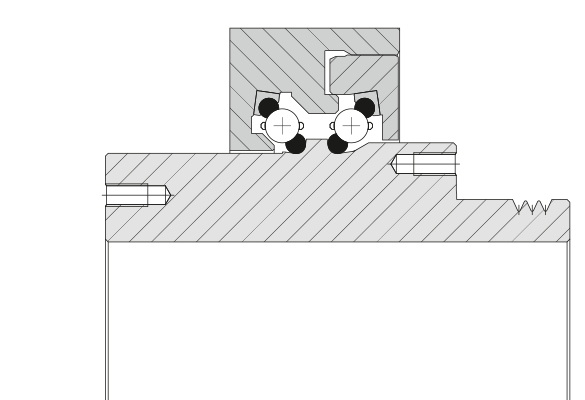

Characteristics: Precise design for maximum performance

The bearing assembly with segmented motor is characterised by its unique structure. The integrated motor, whose stator windings only cover the upper half of the bearing, enables an impressive performance of up to 300 revolutions per minute. This innovative design ensures an optimal balance between power and weight, resulting in exceptional performance.

Image: 2-row angular contact ball bearing with segment motor for computer tomographs.

Special feature: Overcoming gravity - an evolution in bearing technology

The key special feature of the segment bearing is the electromagnetic force of the motor acting upwards on one side. This reduces the gravitational force acting on the rotor, which relieves the integrated bearing of the weight of the rotor. The result is a relieved mode of operation and thus a considerably longer service life compared to conventional bearings.

Applications: Highly dynamic rotary movements

Bearing assemblies with segment motors are used in devices and machines in which bearings are used vertically at high speeds. Examples include processing machines and computer tomographs. The precise and low-load operation makes them ideal for scenarios in which the highest demands are placed on performance.

Advantages: Longer service life and contribution to sustainability

The advantages of this innovative bearing solution are manifold. In addition to their impressive service life and extended maintenance intervals, bearing assemblies with segment motors make a significant contribution to sustainable design. By reducing wear and optimising operation, they help to conserve resources and minimise the ecological impact.

Running performances of up to one billion revolutions are possible without any problems. The total cost of ownership more than makes up for the slightly higher purchase price.

The fusion of innovation and technical excellence in bearing assemblies with segment motors redefines the standards in the bearing industry. This development not only promises efficiency and precision, but also paves the way for a more sustainable future in industrial manufacturing.

At a glance

Precision

Dynamic

Economical

Technical advice and further information:

Stephan Kuhn, Technical Sales

Tel. +49 7361 920-180

s.kuhn@franke-gmbh.de

2-row ball bearing with segmented direct drive (torque motor), Ø 1050mm

| Max. speed: | 300 rpm |

| Noise development at 300 rpm | 66,7 dBA |

| Noise development at 200 rpm | 61,4 dBA |

| Synchronisation as a percentage of the nominal speed | +/-1% |

| Service life due to almost load-free running: | 1 billion revolutions |