Application example Battery production

Requirements

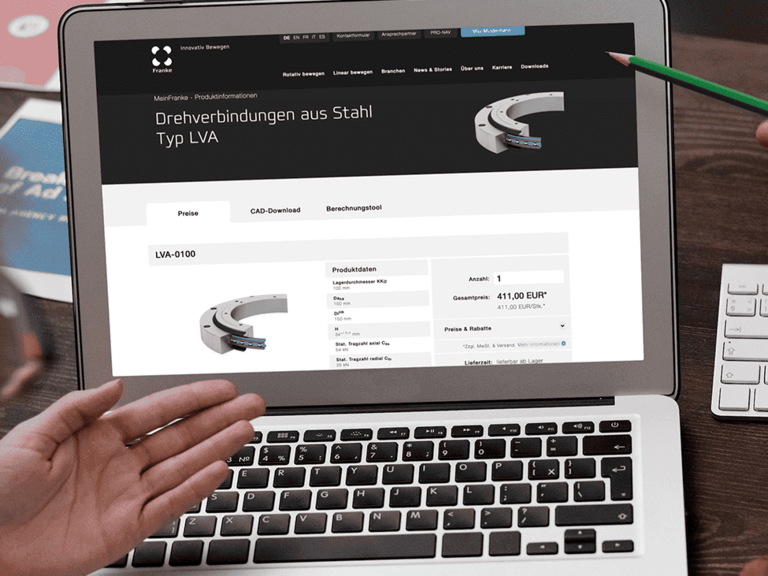

A Franke slewing ring type LVA with a ball and cage assembly diameter of 800 mm is used. In particular, the large centre clearance and the easy, smooth running of the slewing ring are the key product advantages. They ensure trouble-free alignment of the X-ray radiation and high image quality. The backlash-free pre-tensioned slewing ring allows high speeds in order to keep the inspection time per battery cell as short as possible.

Solution

Franke slewing ring type LVA-0800.

Bearing solution used

Benefits

Franke slewing rings impress with their large centre clearance, smooth running and high precision. In this case, ease of movement and adjustability of the rotational resistance were basic requirements for adapting the existing motor to the bearing.