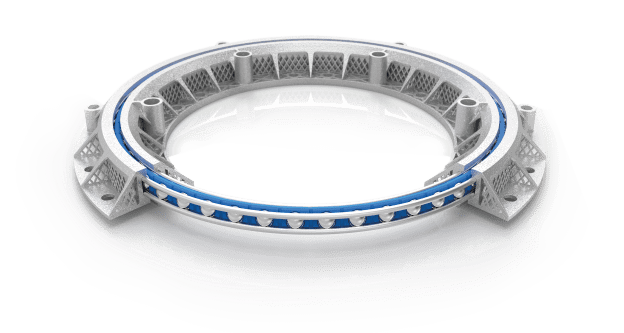

The principle of wire race bearings

The wire race bearings integrated in an enclosing housing absorbs forces from all directions. In order to adapt wire race bearings to the requirements of the application, there are numerous options with regard to wire profile, bevel, ball diameter and material. By using lightweight materials and the latest manufacturing techniques, lightweight bearings from Franke enable substantial weight, energy and space savings with comparable rigidity and maximum precision over the entire service life.

The advantages are apparent:

- Alternative materials such as 3D printing, high-strength plastic or carbon enable significant weight savings.

- Low moving masses ensure energy efficiency and smooth running.

- A free design of the surrounding construction enables savings in connected assemblies.

- Many lightweight materials have positive secondary properties, such as low material expansion or non-magnetism.

Through investigations and analyzes, the surrounding parts of bearing assemblies can be designed in such a way that the use of materials and wall thicknesses meet the loads that occur.

However, there are often limits to the definition. Not everything that looks good on the CAD screen can be realized. This is where both production-related restrictions in cutting production and economic restrictions, particularly in mold making, come into play for CFRP blanks.

3D printing shuffles the cards

In 3D printing, objects are built up in layers from metal particles. One speaks here of additive processes. This means a reversal of conventional manufacturing methods, which usually involve the removal of material.

The layered structure of the parts opens up completely new possibilities for design. Internal honeycomb structures, variable wall thicknesses and even a mix in the nature of the material are possible and help to design even more delicate and lighter. Another advantage of this technology is the quick availability. An appropriately configured CAD file is sufficient to set the printer in action. Shortly afterwards the required parts are available for further processing. From batch size 1, 3D printing is the ideal form of production since no tools are required.

There are a number of advantages for customers of 3D-printed lightweight bearings from Franke:

- extremely low weight and compact design

- customized design

- Bearing diameters currently available from 80 - 300 mm (larger diameters on request)

- Lot size 1 possible with quick availability

The weight saving of 3D-printed bearing assemblies compared to conventional bearings is striking. With the same bearing diameter and the installation of a comparable wire race bearings in the housing rings, the weight saving compared to a conventional steel bearing is almost 90%.