Sustainability and resource conservation are also important topics in mechanical engineering. Repairing machines and components instead of scrapping them is in many cases the better approach, to maintain or even increase the efficiency and profitability of a production plant. Franke wire-race bearings can support you with this.

Bearing assemblies with integrated wire-race bearings have a long service life. But even if the wire-race bearing has reached the end of its service life, the elaborately manufactured housing parts can still be used. They are not directly exposed to the stresses of the bearing and are therefore often still in good condition.

Up to 60% cheaper than a new purchase

Often, it is sufficient to replace individual components such as race rings, balls and cage to restore the bearing to full functionality. This saves time and costs and is a valuable contribution to the conservation of resources and the protection of the environment.

Especially in the case of complex housing parts with complicated geometry or made of exclusive materials such as stainless steel, retreading quickly pays off.

In the Franke archives, the special geometric characteristics of all the wire-race bearings ever manufactured are saved. Previously in hand-written documentation and now in digital databases. The technical specifications even of bearing assemblies from the late 80‘s of the last century can be used to replace the wire-race bearing to be renewed 1:1.

The refurbishing-service of Franke

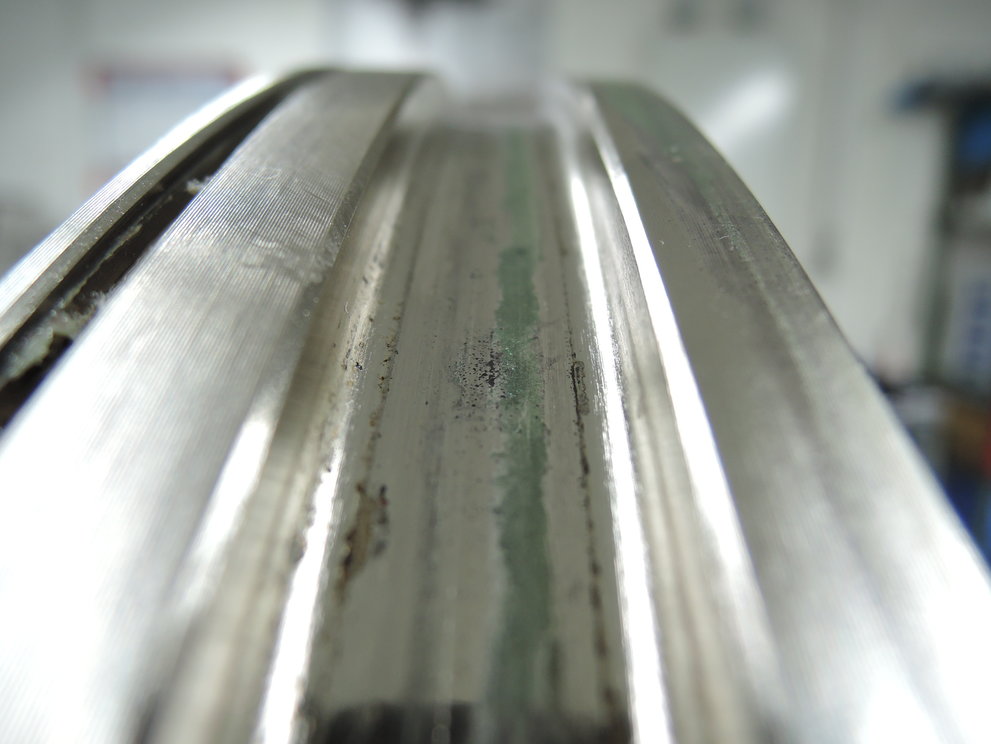

If Franke bearing assemblies approach the end of their estimated service life, the bearing is removed and sent to Franke for inspection. There an initial visual inspection is carried out and the possibilities for retreading are assessed.

If the external conditions of the bearing justify a revision, the bearing is opened and disassembled into its individual parts. Even at this stage, Franke specialists recognise the existing recycling potential and can provide the customer an offer.

If the customer gives the OK, the parts are cleaned and measured. Then a new bearing element consisting of race rings, balls and cage is manufactured and inserted into the existing housing parts. After assembly, the bearing is inspected in accordance with current quality standards and, if necessary, goes through test runs on suitable test rigs. If all specifications are reliably met, the bearing is returned to the customer. There it can be fitted again and provide movement as if nothing had happened.

Refurbishing at Franke – sustainable, quality assured & competent

Certified procedures and processes guarantee the highest level of quality assurance and reliability at all times. This applies equally to new products and to repairs. As a development partner, Franke engineers and consultants are happy to provide information about the possibilities available in individual cases for the cost-effective repair of wire-race bearings. Especially in today’s cost-saving and sustainable production of goods, the idea of repairing tried and tested products instead of constantly purchasing new ones is becoming more and more important. Wire-race bearings from Franke are ideal components for this purpose.