Highly dynamic bearings for baggage scanners

Security

Highly dynamic roller bearings with large centre clearance and particularly quiet running ensure razor-sharp X-ray images of baggage at numerous security gates worldwide.

Precise. Quiet. Highly dynamic.

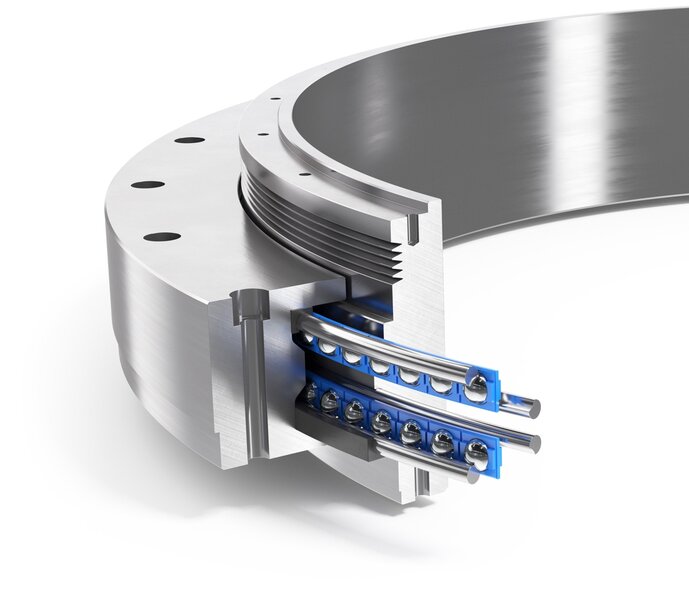

Ground raceways, adapted to the diameter of the rolling elements, ensure high load capacity and precision. Elastomer inserts between the raceways and housing parts prevent the generation of structure-borne noise. Arranged as double-row angular contact ball bearings, Franke wire race bearings have low rotational resistance and enable dynamic acceleration.

Possibilities

instead of specifications

Franke wire race bearings can be used in a wide variety of constructions. The demands on the surrounding structure are low, as it is not directly exposed to the loads. The main load is borne by the wire race bearing. This means that you are virtually free to determine the ideal shape and material for your further construction.

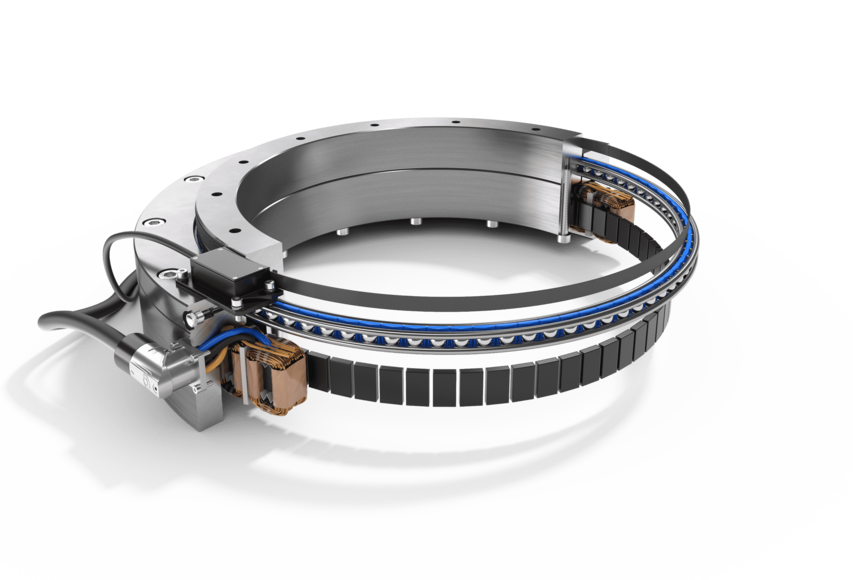

With direct drive as a complete system

Franke rolling bearings for baggage scanners are also available complete with an integrated torque motor as a direct drive. The integration of the drive into the bearing housing means that wear-prone assemblies for the transmission of drive power such as toothed belts, pinions or gears can be omitted. This reduces maintenance costs, increases efficiency and improves both the speed range and positioning accuracy.