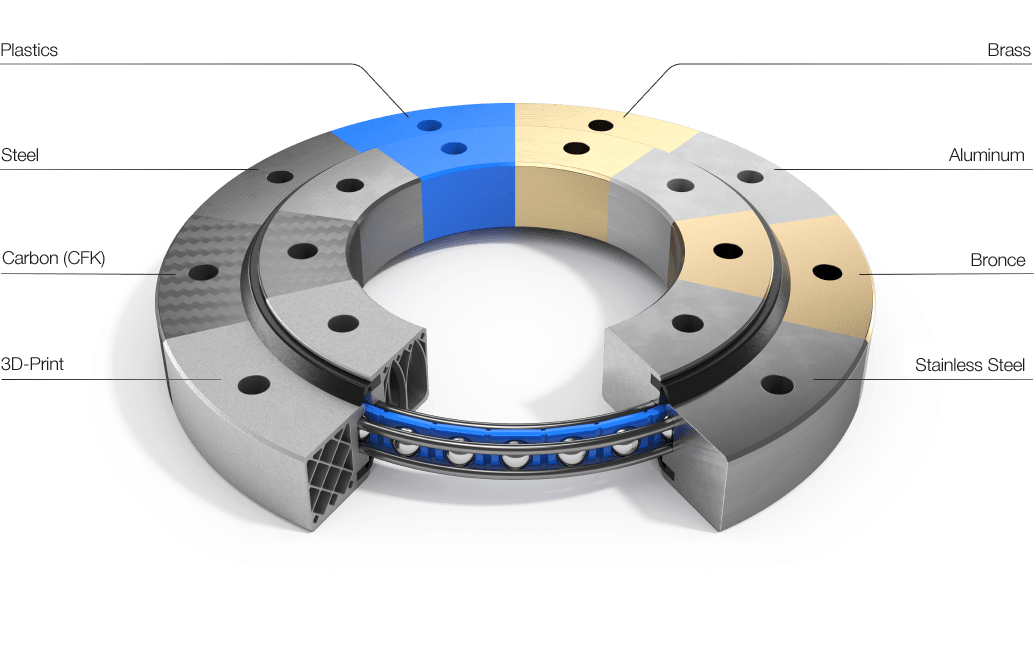

Fields of Innovation Alternative materials

Free choice of material for the bearing housing -

the Franke principle makes it possible

Steel

We use C45N, an unalloyed quality steel, as a proven material for standardised slewing rings. This is characterised by its excellent machinability, which enables precise production with high roundness and flatness accuracy. In addition, this material offers an attractive price-performance ratio compared to high-alloy steels.

Steel slewing rings are used in many areas of application, especially in plant and mechanical engineering.

Amagnetic steel

Amagnetic steels, such as the austenitic stainless steels 1.4404 and 1.4435, are characterised by their high toughness and are particularly resistant to shock loads and vibrations. In combination with silicon nitride (Si₃N₄) balls, non-magnetic rolling bearings offer outstanding performance. Silicon nitride impresses with its low density, high strength and excellent wear resistance, making the bearings not only lighter but also more durable. This combination of materials is ideal for applications that require the highest precision and maximum durability.

Thanks to its properties, amagentic steel is particularly suitable where electromagnetic fields must be avoided or extreme precision is required. However, it is also used in the semiconductor industry, for example in the manufacture of chips or in the electronics sector.

Stainless steel

Stainless steel is the material of choice for food processing and food packaging machinery. In some cases liquids are filled here and aggressive cleaning agents act on the bearings. Roller bearings made of stainless steel usually have complex seals to prevent the ingress of liquids. If this is not sufficient, raceways and rolling elements can also be made from stainless steel components.

Aluminium

Aluminium has been a proven material for bearing housings for decades. By using aluminium housing parts, the weight of conventional steel bearings can be more than halved. Due to the integration of a 4-point bearing with inserted steel races, these can absorb the resulting loads and torques.

This material is always used when the aim is to save weight. For this reason, it is often used in the aerospace industry.

Plastic

Plastic bearings can be manufactured from various polymers to fulfil the desired requirements. Thanks to their low weight (up to 80% lighter than steel) and smooth running, they are wear-resistant and reduce energy requirements. The forces are absorbed by the integrated wire race bearing.

By using 3D-printed housing parts in slewing rings, fibre-reinforced structures can be produced in a targeted manner. At the same time, there is a wide range of materials that can be used for printing, including polycarbonate, ABS (acrylonitrile butadiene styrene) and various fibre-reinforced plastics.

Plastic bearings are used in a wide range of applications. They are used in conveyor technology, handling equipment or in filling systems in the food or pharmaceutical sectors.

Carbon (CFK)

The specific weight of CFRP is around 75 per cent lower than that of a steel structure. The enormous variety of processing options for carbon fibres to create complex materials with the highest load-bearing capacity is another reason for the popularity of CFRP in lightweight construction. Carbon housings can be fitted with aluminium sleeves for bolting to the adjacent construction. Load ratings, rigidity and temperature behaviour correspond to similar slewing rings made of aluminium.

Franke wire race bearings can be integrated into any enclosing structure made of CFRP and enable the construction of extremely compact and ultra-light slewing rings.

Further material options for wire race bearing housings

In addition to classic steels and stainless steels, alternative materials that offer special properties for specific areas of application can also be considered. Thanks to the unique technology of the 4-point bearing, many things seem possible.

Have you ever thought about the following materials?

Non-ferrous metals are characterised by high corrosion resistance and good sliding properties. Bronze is often used in maritime applications or in heavy industry, as it has self-lubricating properties and functions reliably even under high loads. Brass, on the other hand, is particularly suitable for precision mechanicsand instrument making, where it is valued for its high dimensional accuracy and aesthetic appearance.

Although wood is rather uncommon in technical applications, it can be advantageous in special constructions. Hardwood offers high strength at a comparatively low weight and can be made resistant to environmental influences through special impregnations. Possible applications include the furniture industry, historical replicas or special machines in the preservation of historical monuments where modern materials are out of the question.

With its high rigidity and excellent vibration damping, cast iron is a proven choice for highly loaded slewing rings in machine tools or press systems. It minimises vibrations and thus ensures improved precision of moving machine parts. It also offers high wear resistance, which extends the service life of components.

Could there be more?

Regardless of the material your housing is made of - we will work with you to develop the right solution, even for unusual materials. With Franke 4-point technology and inlaid raceways, the possibilities are virtually unlimited.

Contact us

Thorough coordination is the basis for every successful project.

I would be happy to advise you personally

Christian Burghard

Technical consultant

Tel: +49 7361 920 124