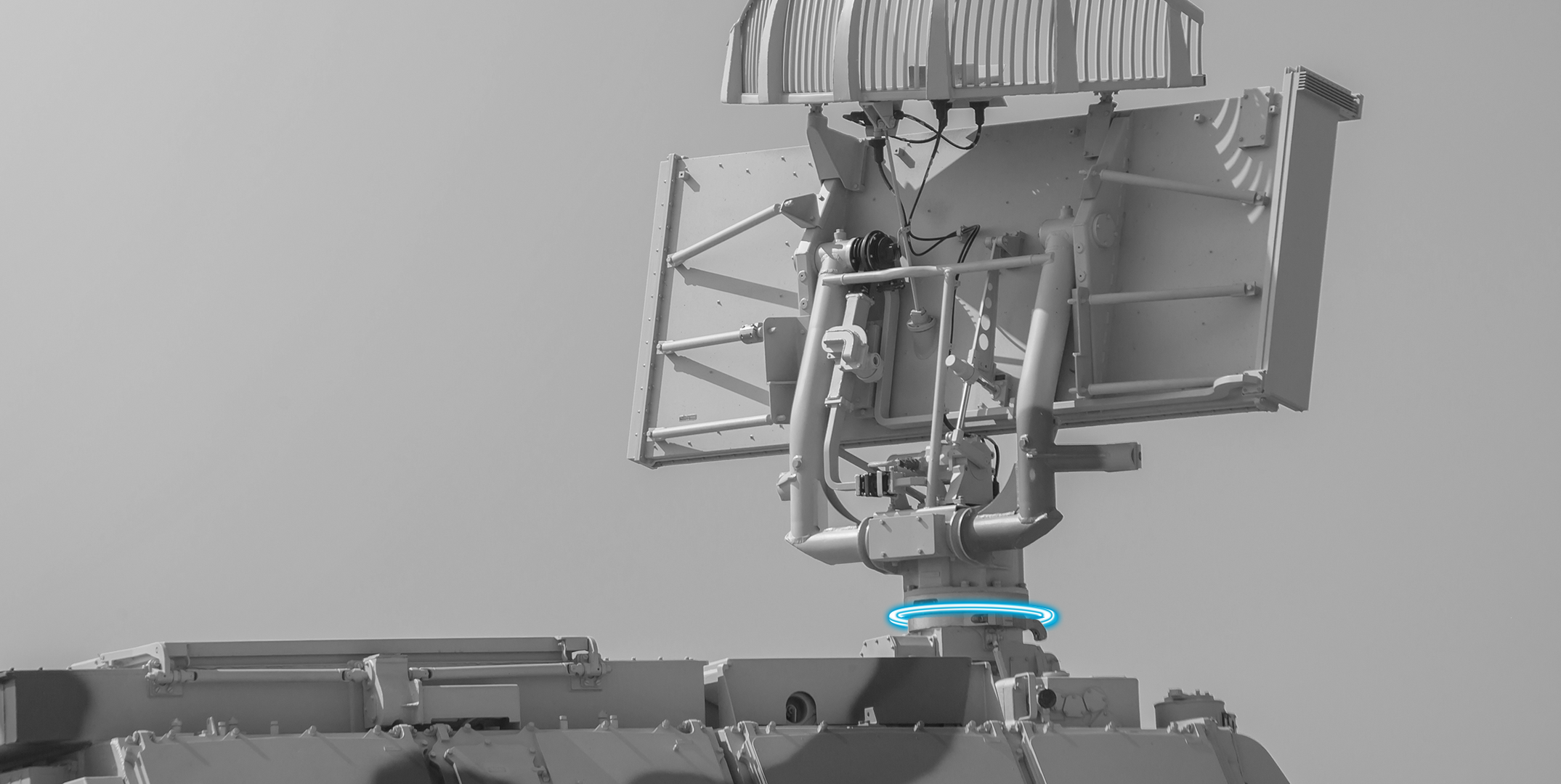

Robust bearings and drives for radar systems

Radar

Robust bearings with large centre clearance for land and sea-based radar systems, optionally with gearing for conventional drive or with integrated torque motor.

Rotative movement

under all operating conditions.

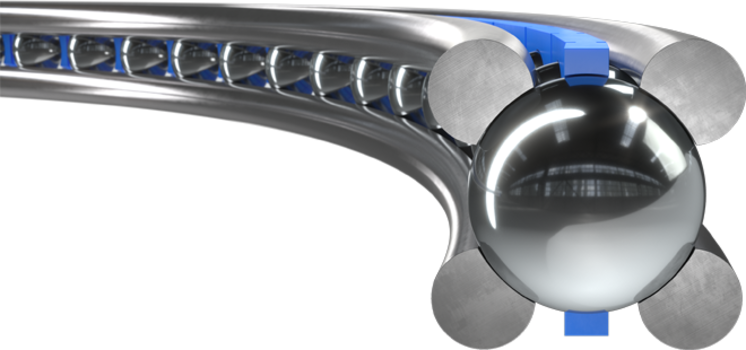

Franke wire race bearings are based on a special principle. The rolling elements do not move directly on the bearing shells but on tough raceways that are inserted into the bearing housing. This gives you completely new possibilities for the design and choice of materials for your application. Franke wire race bearings can be customised in many ways.

Possibilities

instead of specifications

Franke wire race bearings can be used in a wide variety of constructions. The demands on the surrounding structure are low, as it is not directly exposed to the loads. The main load is borne by the wire race bearing. This means that you are virtually free to determine the ideal shape and material for your further construction.

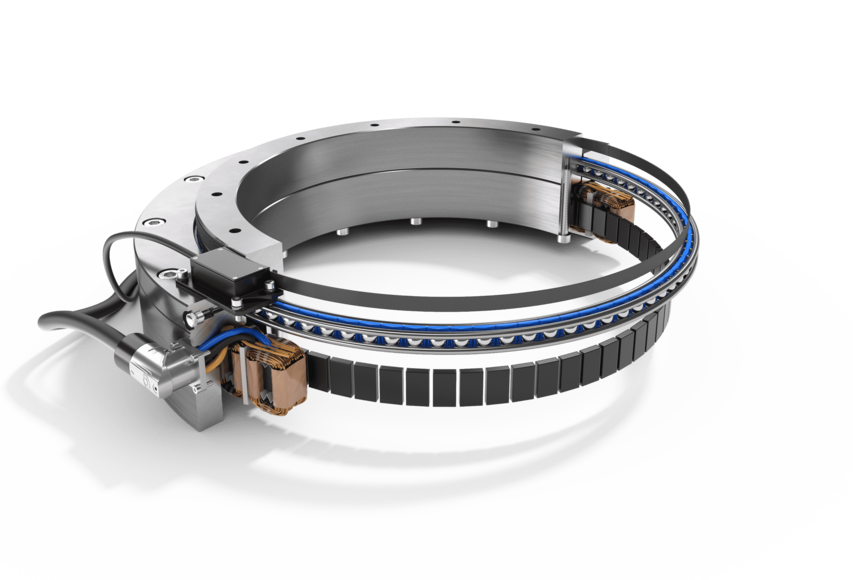

With direct drive as a complete system

Franke bearings for radar systems more than fulfil the high requirements for torque load capacity, insensitivity to environmental influences and the desire for a long service life. As early as the development phase of an individual solution, the expected forces are visualised using calculations and FEM analyses and taken into account in the design and choice of material for the housing parts. On request, we can complete the rolling bearing with ready-to-install direct drives up to 1800 mm in diameter and painted to military standards.