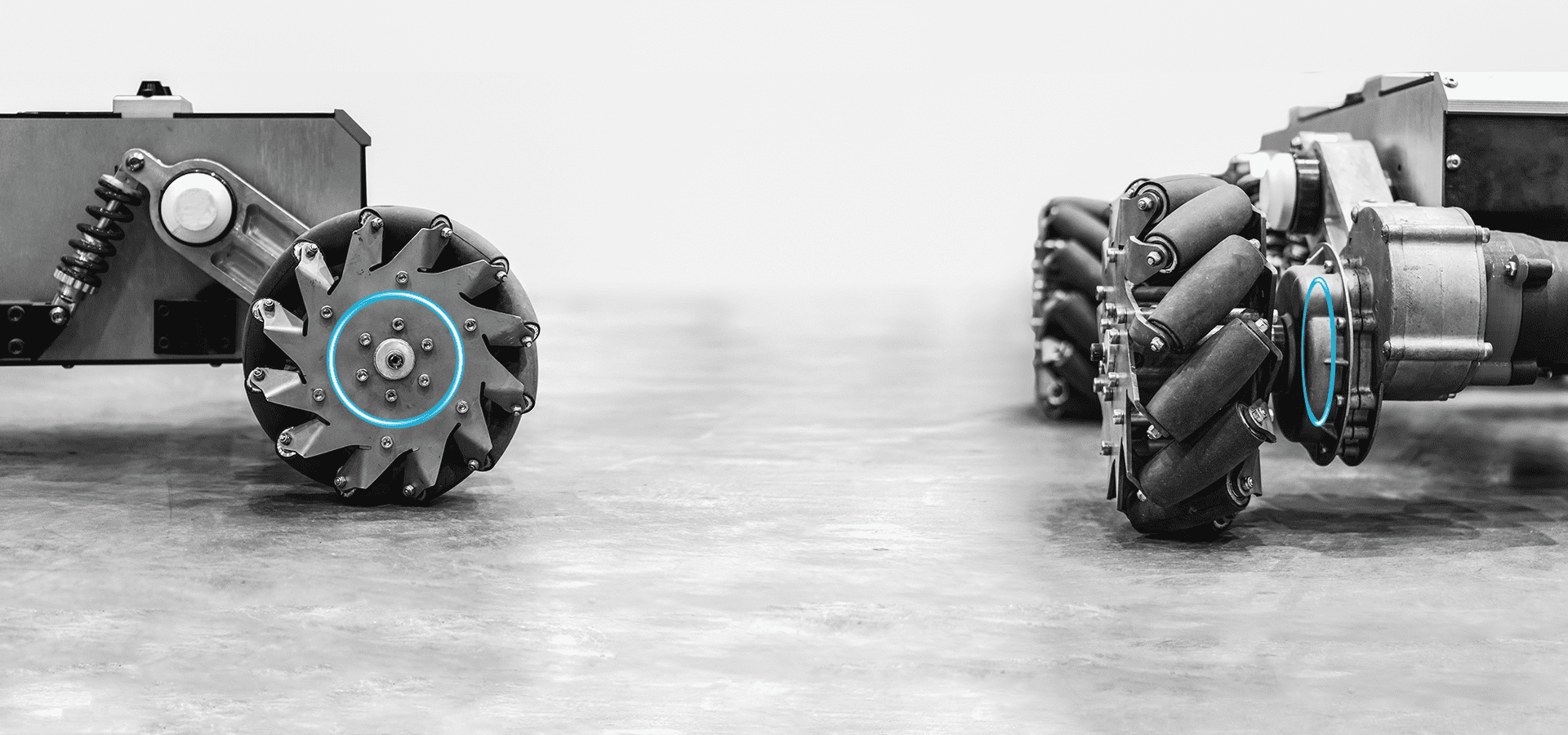

Application example Omnidirectional automated guided vehicle system (AGV)

Requirements

Mecanum wheels of an omnidirectional AGV, very compact, simple and rigid bearing arrangements are required. Furthermore, a minimum installation space and higher tilting moments with eccentric loads must be taken into account.

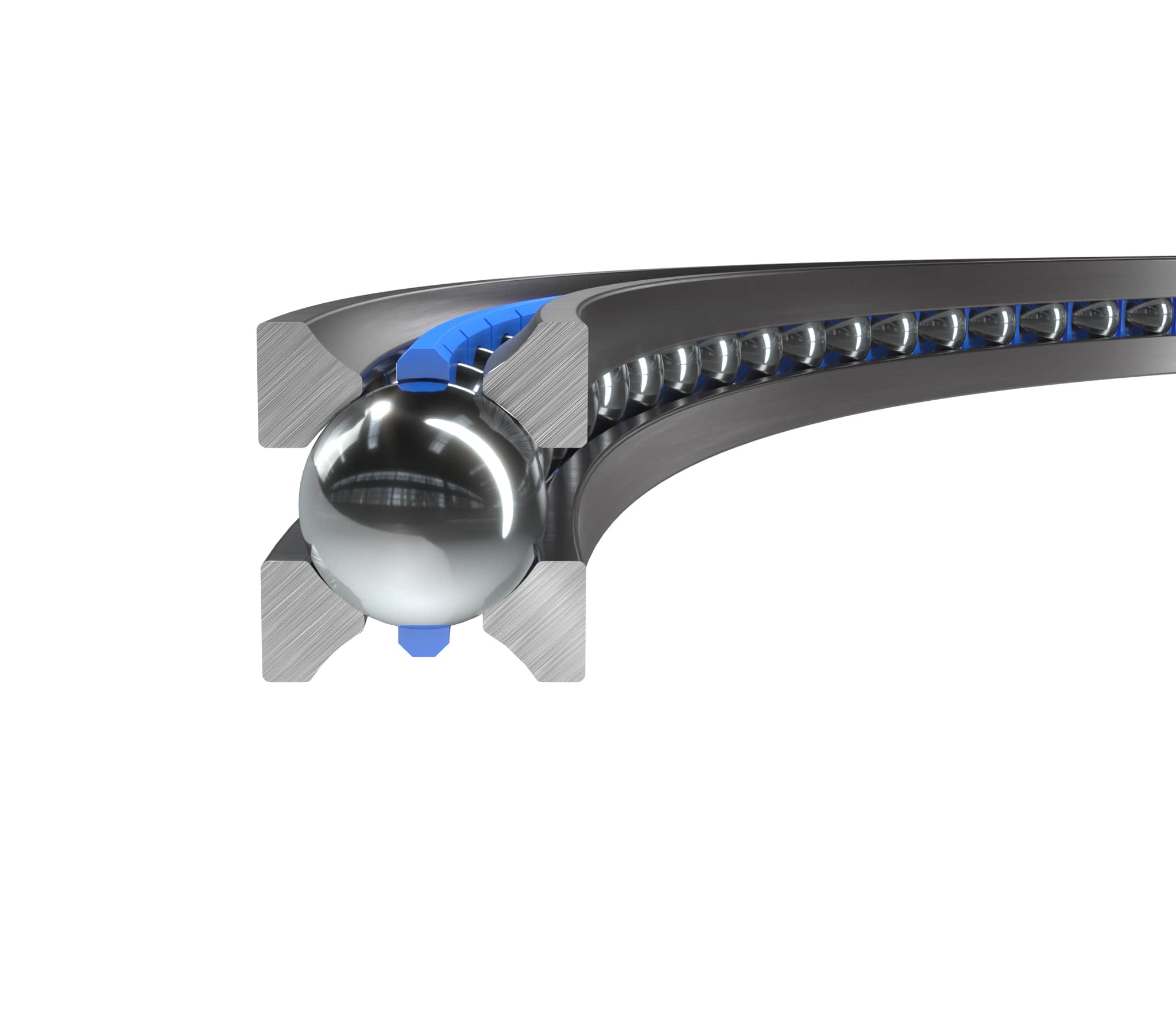

Solution

A double bearing is used for optimized load absorption. This small bearing element can be easily integrated into existing wheels. The outer and inner diameters remain unaffected.

Bearing solution used

Advantages

The compact and rigid rectangular profile of the LER2-120 allows the customer's load requirements to be met. A one-piece plastic band cage with retained rolling elements facilitates mounting in the Mecanum wheel. In addition, the space saving design made it possible to accommodate an internal lip sealing. This modular system has already been successful with several customers in the handling and automotive industries.

Installation space, weight, efficiency:

how you can optimise your drive units

The choice of bearing determines the performance of your drive system.

In this whitepaper, you will learn how wire roller bearings create new design possibilities and why leading manufacturers already rely on Franke.