Application example Pipe measuring system

Requirements

In non-contact pipe measurement, precision is paramount. The pipes are designed to be sufficiently thick to ensure structural integrity while being kept as thin as possible to minimize material costs.

The measurement system, seamlessly integrated into the production line, ensures that wall thickness as well as inner and outer diameters consistently meet the specified target dimensions. To achieve this, one or more transceivers rotate continuously, emitting and receiving frequency-modulated millimeter waves for precise data acquisition.

The rotational movement requires a compact slewing ring with low rotational resistance, which maintains smooth operation even under asymmetric loads and allows for easy installation.

Solution

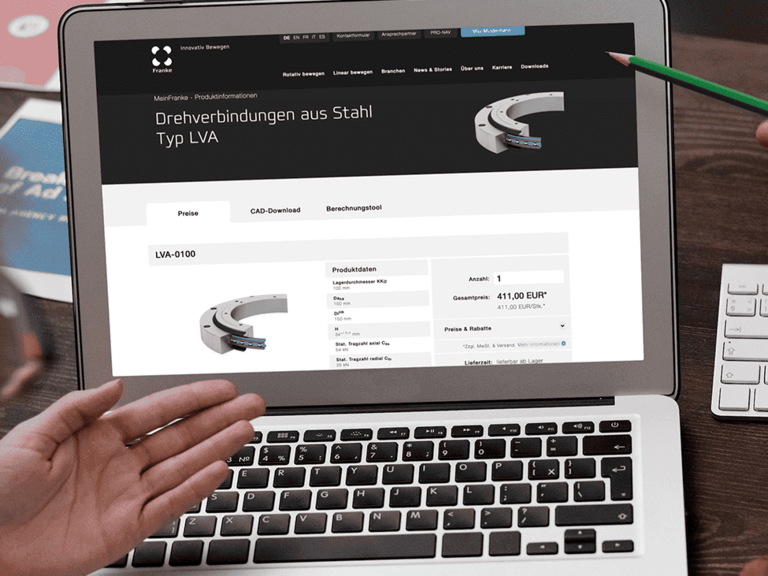

A customized slewing ring made of steel ball bearing LVA-0600-Z with special bore pattern and knurling on the outer ring.

Bearing solution used

Benefits

The slewing ring features a compact design, allowing easy external bolting to the housing through a specially developed hole pattern. This design ensures operational stability even under asymmetric loads while maintaining smooth rotational behavior.

The simplified installation process eliminates the need for post-adjustment, significantly reducing assembly time. Additionally, the outer ring of the slewing ring is knurled, enhancing grip in combination with the friction wheel and thereby improving operational efficiency.