Application example Thread testing of pipeline pipes

Requirements

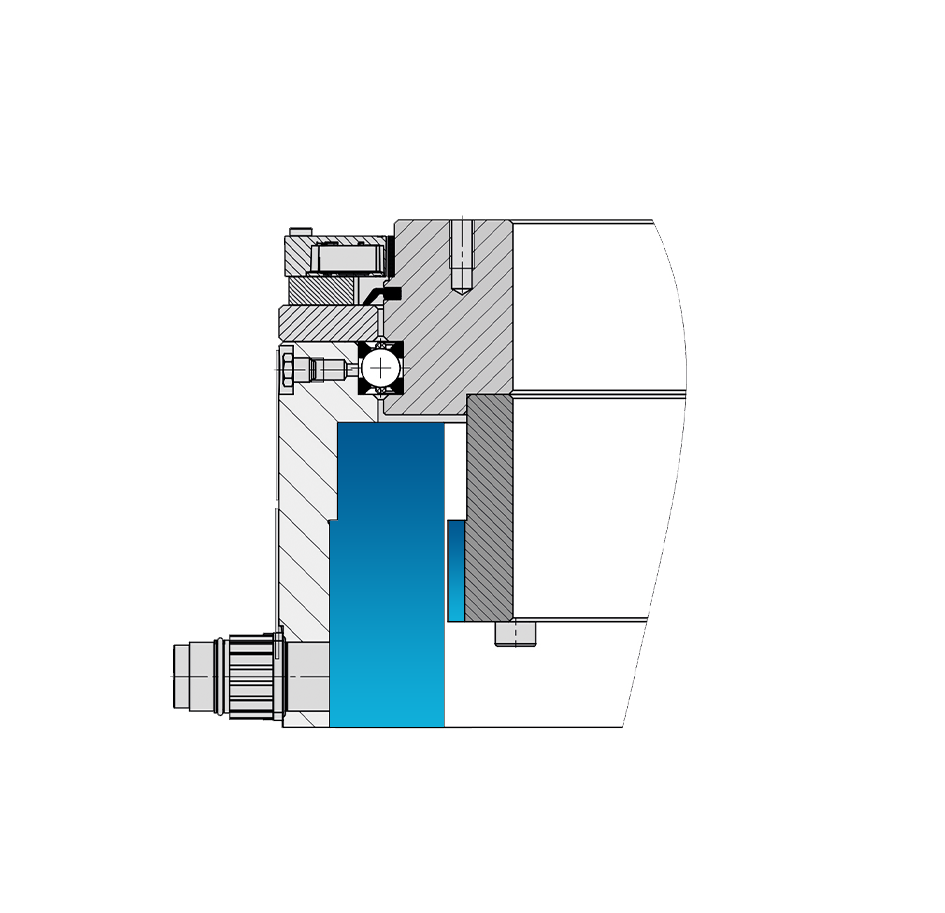

Testing the threads of pipeline tubes is a dynamic and high-precision process. For exact positioning of the measuring device, a high positioning accuracy as well as a radial and axial runout of 0.02 mm is required. An existing SEW servo controller provided by the customer is to be reused.

Solution

Customized slewing ring with integrated torque motor LTD-385-Z in special design.

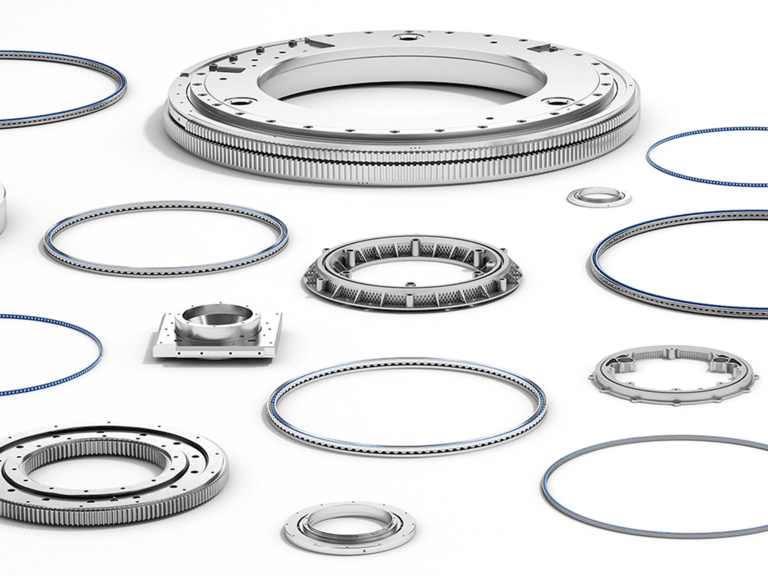

Bearing solution used

Advantages

The integrated torque motor meets all requirements for dynamics and precision. The compact design and the large center clearance allow ideal placement of the measuring equipment. In the special version, the torque motor is equipped with 2 measuring heads and a temperature sensor as a feedback transmitter.

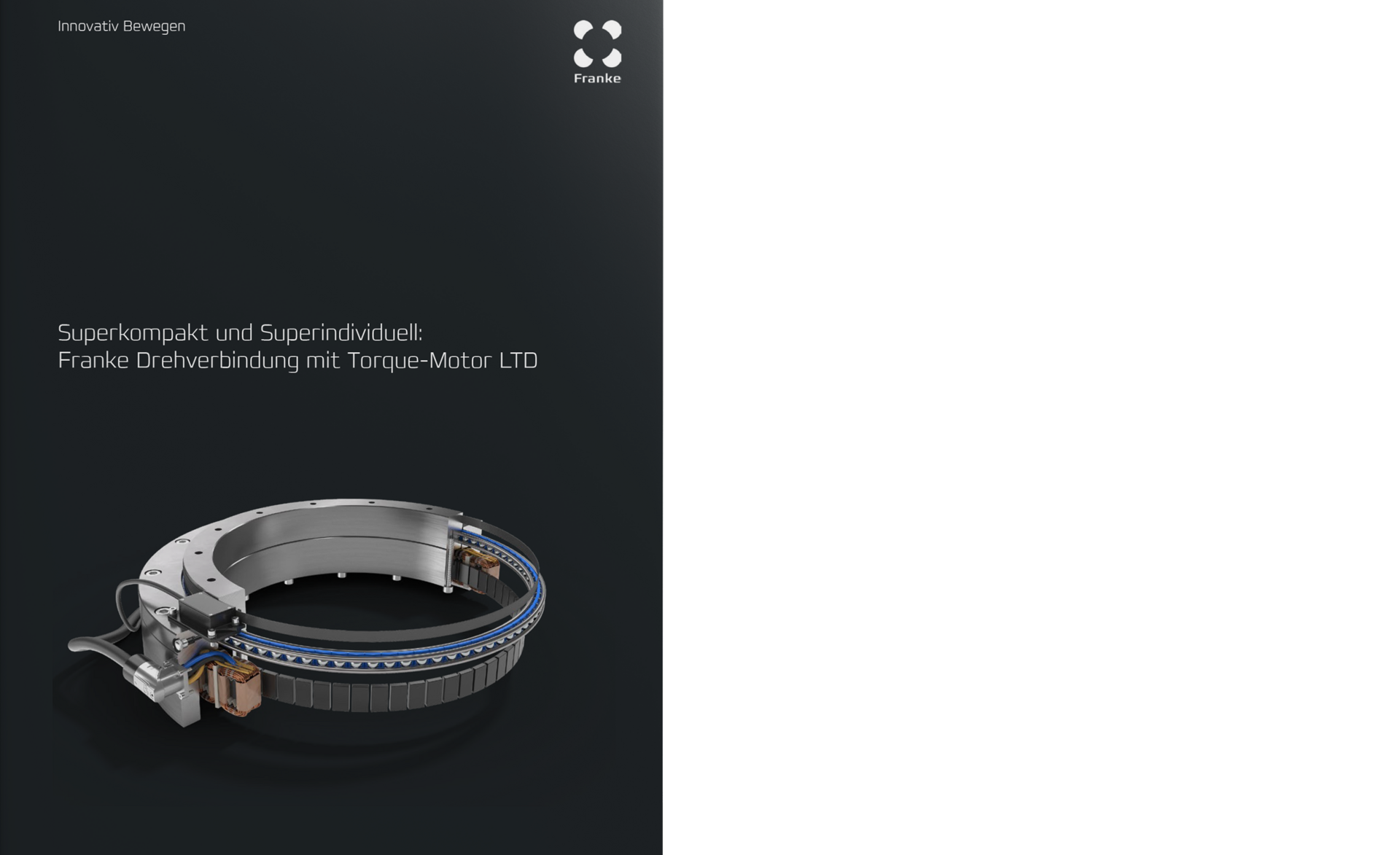

Whitepaper slewing ring with torque drive

Find out more about slewing rings with integrated torque motor and why it is superior to other drive types in almost every respect.

In future, dispense with components such as gearboxes and drive pinions.