FAQ Packaging machines

Frequently asked questions

Depending on the design, our components are corrosion-resistant, easy to clean, free from lubricant leakage and compatible with current hygiene regulations.

Stainless steel, food-grade plastics or special coatings are particularly suitable for the integration of roller bearings or linear guides in packaging machines. These provide corrosion protection and fulfil the necessary hygiene requirements.

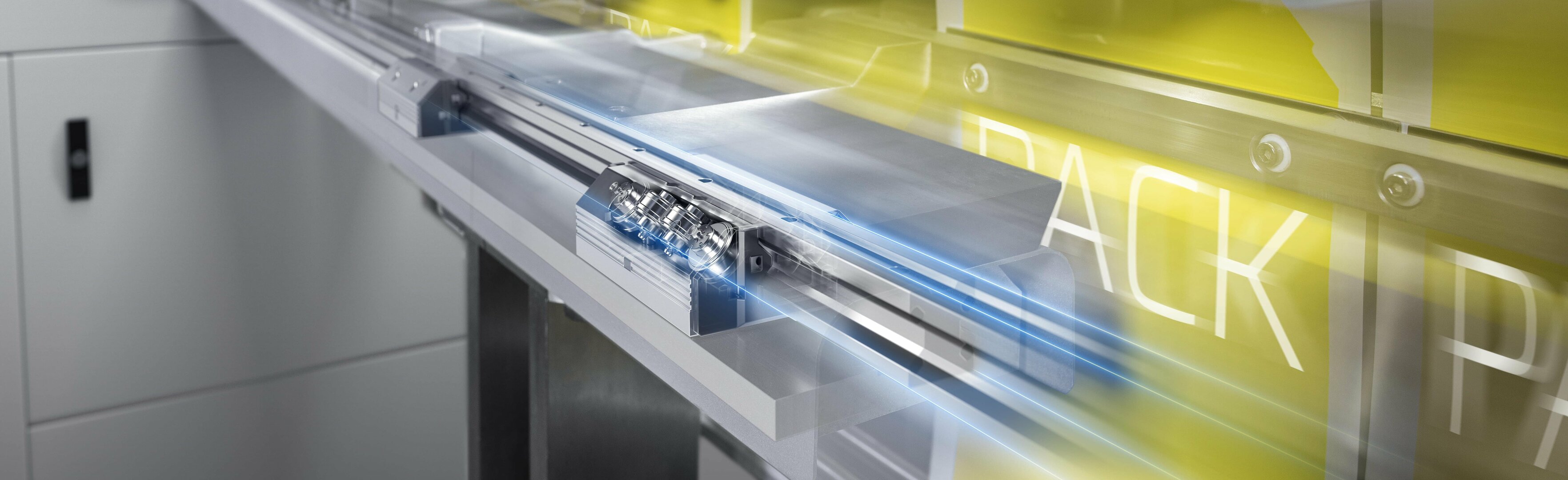

FDG and FDC linear guides have proved particularly successful in the food packaging sector in the past.

The selection of the optimum rolling bearing or the best slewing ring depends on factors such as load, speed, ambient conditions and available space. We will be happy to advise you.

To define your requirements in advance, please use our design form, which will help you to find a suitable solution together.

Slewing ring configuration form

Yes, 95% of our daily work consists of the production of customised rolling bearing and linear guide solutions for customer-specific applications.

If you require detailed information about your project, we will be happy to advise you. You can find your personal contact here.

Some of our solutions are lubricated for life or are low-maintenance or maintenance-free. It depends on the requirements of the respective application whether these products can be used there.

If you require detailed information about your project, we will be happy to advise you. You can find your personal contact here.

The unique Franke 4-point technology, which allows the rolling element to move on inserted raceways, as well as the individually adjustable preload or adjustable sliding resistance, significantly minimises wear. In addition, high-quality materials and optimised lubrication solutions ensure reduced maintenance requirements and higher machine availability.

Slewing rings can be easily renewed by replacing raceways and rolling elements without having to replace the entire slewing ring. Find out more about the repair of slewing rings in our whitepaper.

Thanks to standardised sizes, which are also used by market competitors, and individual customisation options, the integration of Franke products is uncomplicated. Particularly in the area of rolling bearings, you have the option of installing raceways and rolling elements directly in your housing and can therefore dispense with a costly redesign of your machine.

If you have a specific question, please use our contact form.

Yes, our technical support team will advise you on the selection of suitable components for your application and will also be happy to carry out an initial design for you.

Would you like to calculate your load case yourself first? Then register on MyFranke and use our calculation tool.

We also offer installation instructions, which include detailed installation instructions and design tricks for the adjacent construction.

Lightweight materials such as aluminium or special plastics reduce the mass inertia and enable higher accelerations. Thanks to the special 4-point technology of the inserted raceways, this weight saving is particularly possible with rolling bearings and linear guides from Franke.

We would be happy to advise you personally. Find your personal contact here.

Yes, rolling bearings and slewing rings made of corrosion-resistant stainless steel or polymer bearings can withstand frequent cleaning cycles with aggressive chemicals.

Stainless steel or coated slewing rings and polymer bearings are ideal for use in cool or damp production environments. In any case, you also have the option of integrating wire race bearings into your housing design to customise it to the ambient conditions or other requirements. We also offer corrosion-resistant linear guides that have been specially developed for this type of application. In addition, we use a special low-temperature grease to ensure uniform sliding resistance, even at temperatures below 0°C.

Yes, we offer maintenance-free, self-lubricating linear guides that do not require external lubrication and minimise the risk of contamination - e.g. type FDC or type FDG

For slewing rings, we also have a selection of self-lubricating solutions with corresponding sealing concepts.

To check the suitability of the products for your specific application, we recommend a personal consultation. You can find your personal contact here.