Application example End-of-line packaging machine

Requirements

End-of-line packaging machines require reliable and low-maintenance operation. The manufacturer wanted to standardize the linear guides used, and assembly logistics were a decisive factor in this.

Solution

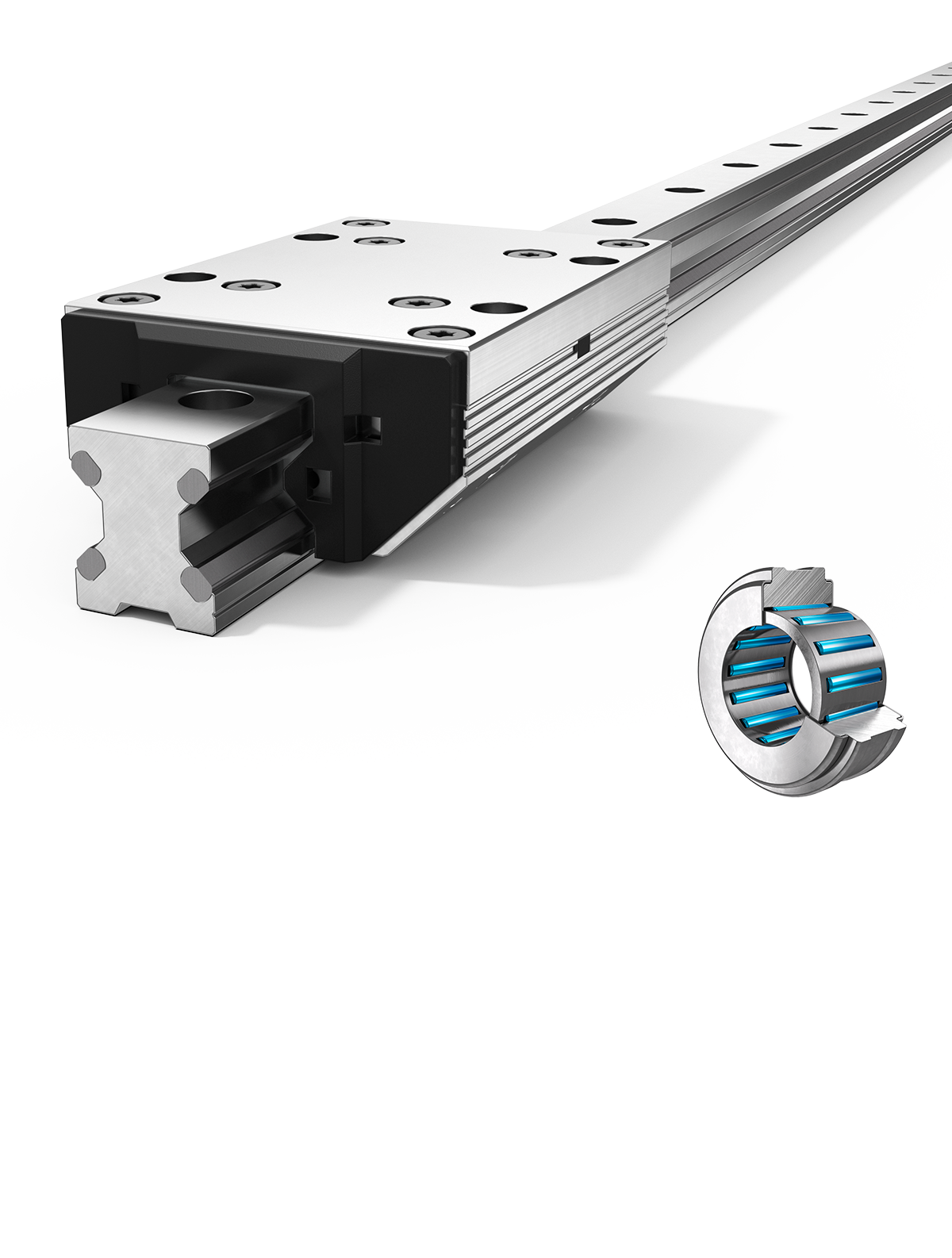

Aluminum roller guide type FDA. The needle-guided rollers offer reliable running behavior, even with high cycles and changing movement profiles.

Linear solution used

Advantages

A modular solution is created by means of sliders pre-mounted on the rails, eliminating the need for additional assembly steps in the system. In the event of replacement, the individual modules can be changed directly without the need for complete disassembly. This makes it easy to adapt additional components manufactured by the customer.

The aluminium components used in the linear guide minimize mass inertia and therefore the energy required. The encapsulated rollers ensure virtually maintenance-free operation, which offers considerable advantages for systems where short downtimes are required. The final assembly of the individual modules can be carried out under load, which is not possible with conventional recirculating ball bearing and guideway elements.

Whitepaper: Linear guides in modern packaging machines

Linear technologies play a central role in increasing efficiency and optimising packaging processes.

They offer flexible customisation options and ensure high cycle rates - two essential requirements for any packaging machine.