Torque drive

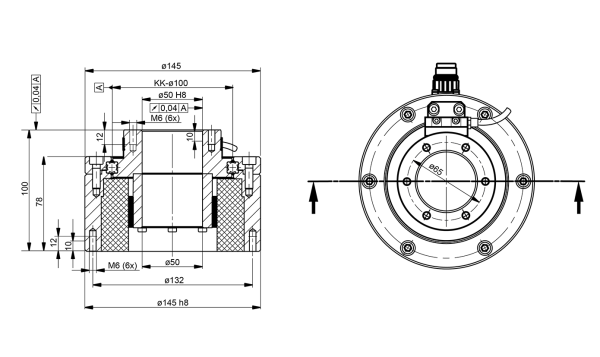

Direct drive type LTD

609818

Material C45N (optionally aluminium)

Operating temperature -10 °C to +80 °C

Mounting position Any

Lubricant With bearing grease via grease nipple

Options Absolute measuring system, axial cable outlet, control units incl. cables, water-cooling

| Accuracy | |

| Speed | |

| Ø-Range | |

| Price |

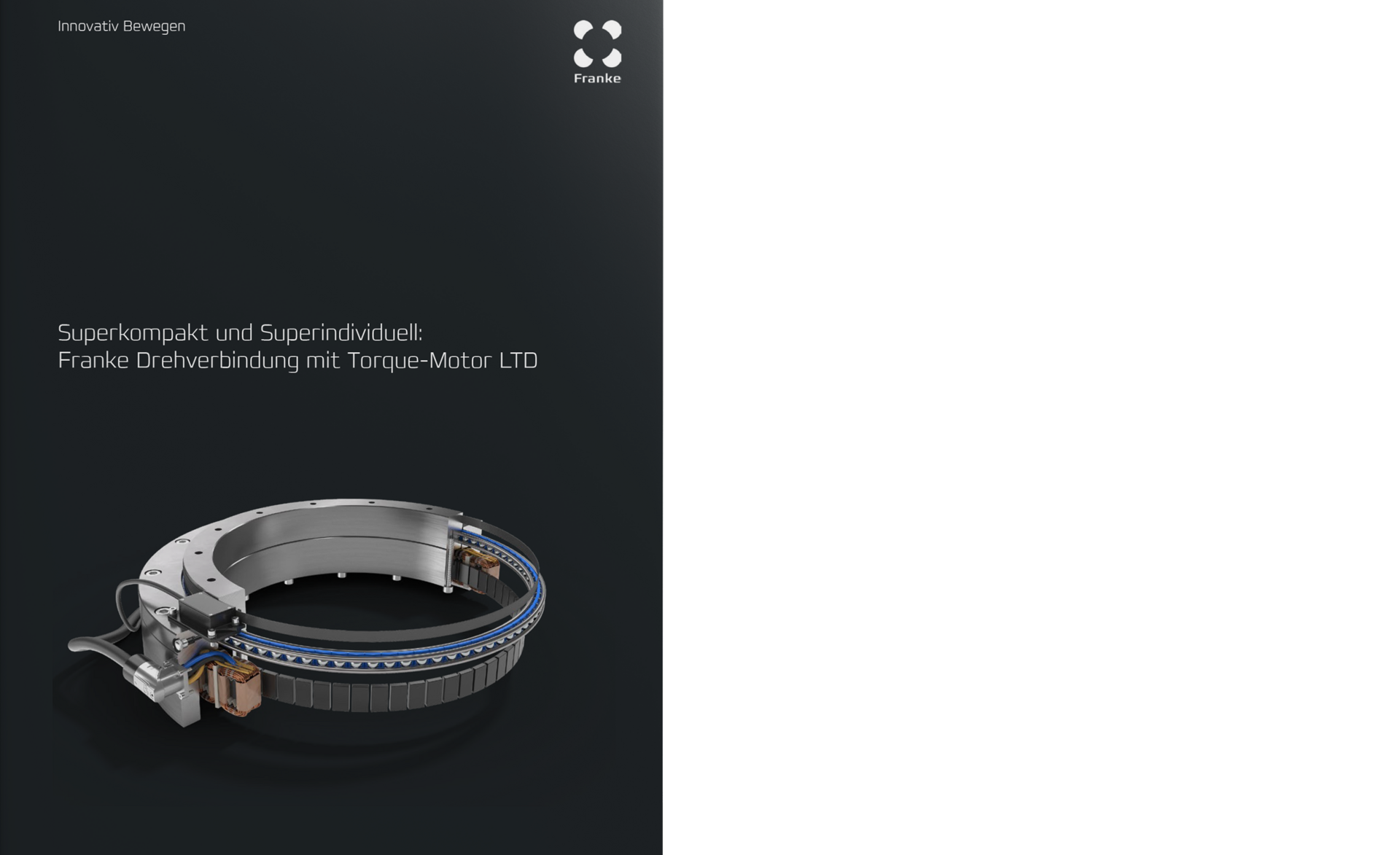

Super compact and super individual: Franke direct drive with torque motor LTD

Basic-Data

- Housing steel or aluminium

- KKØ: 100 - 1800 mm

- Incremental measuring systems

- Absolute measuring systems

The advantages

- Compact design

- Large centre clearance

- Free choice of components

- Four standard sizes from stock

- Customised solutions

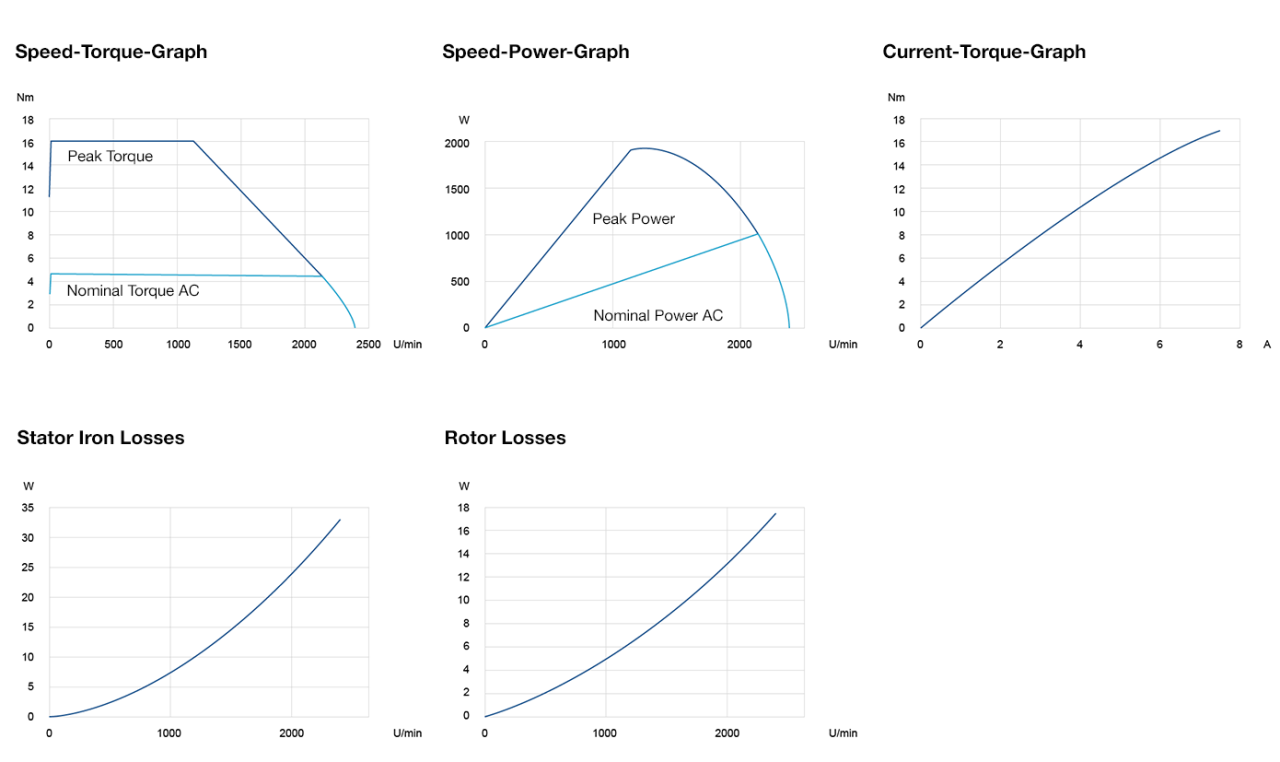

Function & benefits:

Compact

Dynamic

Energy efficient

Compact design, large centre clearance

Franke bearing assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Franke slewing rings with torque motors are certified for use in clean rooms.

Available diameters

Franke bearings with direct drive are available in diameters from 100 mm to 1,800 mm.

My contacts for this product

Your local contact

Franke GmbH

Obere Bahnstraße 64

D-73431 Aalen

Tel.: +49 7361 9200

vertrieb@franke-gmbh.de

Whitepaper slewing ring with torque drive

Find out more about slewing rings with integrated torque motor and why it is superior to other drive types in almost every respect.

In future, dispense with components such as gearboxes and drive pinions.