Franke GmbH is a company that specializes in the development and manufacture of lightweight bearings. Lightweight bearings are special bearing components that enable weight reduction and increased performance through innovative design and materials. Further information is available on the Lightweight bearings innovation page.

Franke offers a wide range of lightweight bearings for various applications, including

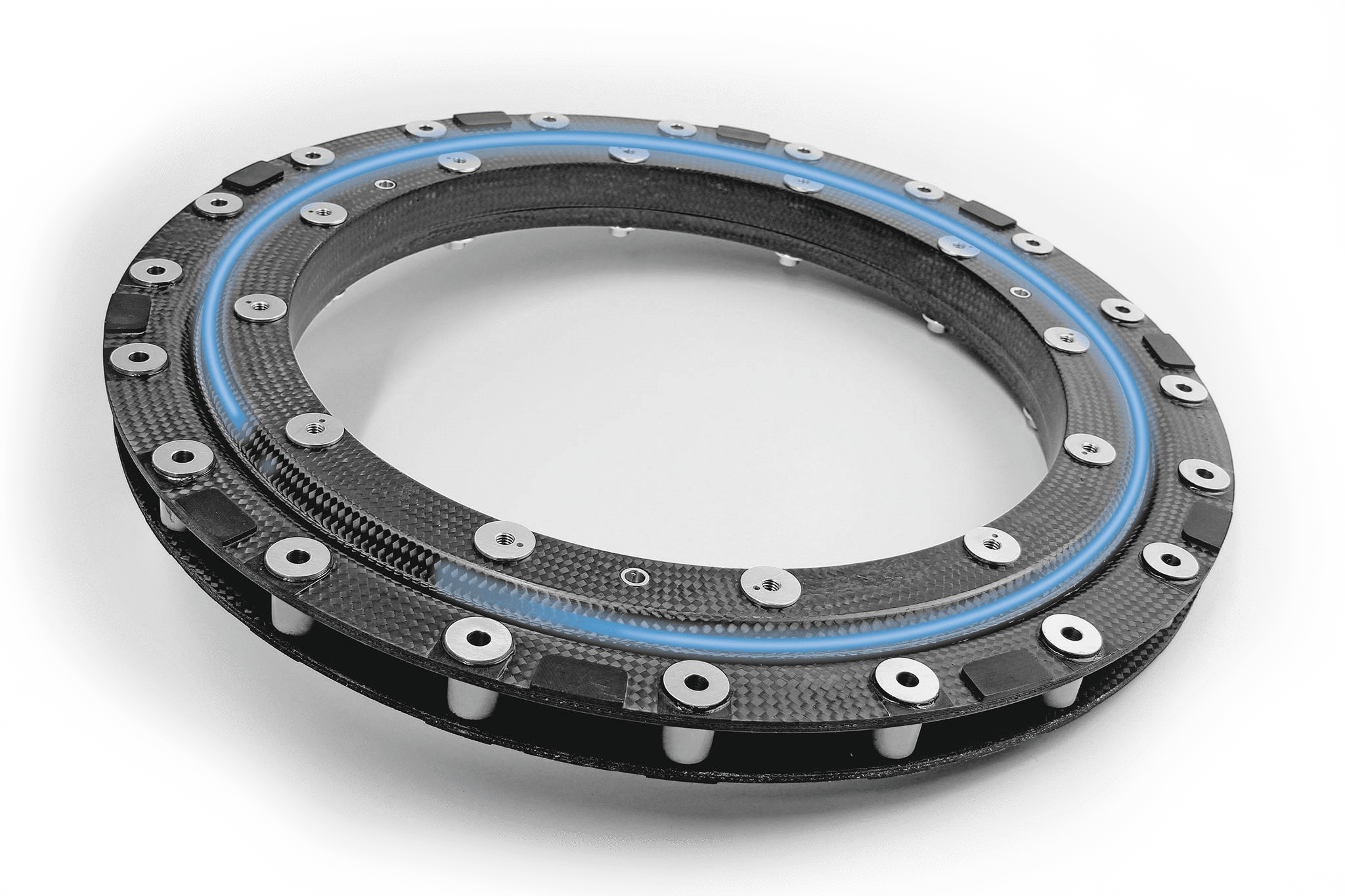

- Slewing bearings: Franke produces high-precision slewing bearings that are suitable for low-weight, high-accuracy applications. These bearings are characterized by their compact design, high rigidity and low friction.

- Swivel bearings: Franke offers swivel bearings designed for use in applications where 360-degree rotation or swivel motion is required. These bearings are characterized by their high load capacity, lightweight design and resistance to environmental influences.

- Precision bearings: Franke manufactures precision bearings that meet the highest standards of accuracy and rigidity. These bearings are often used in applications where precise positioning and movement is required, such as in metrology, optics or robotics.

- Crossed roller bearings: Crossed roller bearings from Franke are characterized by their special design, which enables a high load capacity with a compact design. These bearings are used in applications where a high radial and axial load capacity is required, e.g. in machine tools, robots or packaging machines.

Franke GmbH has many years of experience in the development and production of lightweight bearings and offers customized solutions for specific customer requirements. The bearings are used in various industries, including mechanical engineering, automation, aerospace, medical technology and many others.

Franke's lightweight bearings are characterized by their high quality, reliability and advanced technical features. They help to reduce the weight of machines and systems, improve energy efficiency and increase performance.

Lightweight bearings are made from a variety of materials that offer high strength and rigidity combined with low weight. Here are some of the common materials used for lightweight bearings:

- Aluminum: Aluminum alloys are commonly used for lightweight bearings because they offer high strength, light weight and good corrosion resistance. Aluminum is also readily available and inexpensive to process.

- Titanium: Titanium is a lightweight metal with excellent strength, corrosion resistance and a high stiffness-to-weight ratio. It is often used in demanding applications where extreme lightweight construction is required, such as in the aerospace industry.

- Composite materials: Composite materials, such as carbon fiber or glass fiber composites, offer high strength at low weight. They are often used for lightweight bearings to further reduce weight. These materials can be combined with synthetic resins or metal matrices to achieve the desired properties.

- Plastics: Certain high-performance plastics such as polyamide (PA), polyether ether ketone (PEEK) or polyethylene (PE) are used for lightweight bearings. They offer good chemical resistance, low friction and sufficient strength for many applications.

When selecting the material for a lightweight bearing, various factors are taken into account, such as the load requirements, environmental conditions, service life, costs and specific application requirements. Choosing the right material is critical to ensure optimal performance and reliability of the lightweight bearing.

It is important to note that material selection for lightweight bearings is a complex task that requires careful consideration of various factors. Engineers and manufacturers of lightweight bearings work closely together to identify and use the best materials for the specific applications.