Precise. Dynamic. Reliable.

Intralogistics

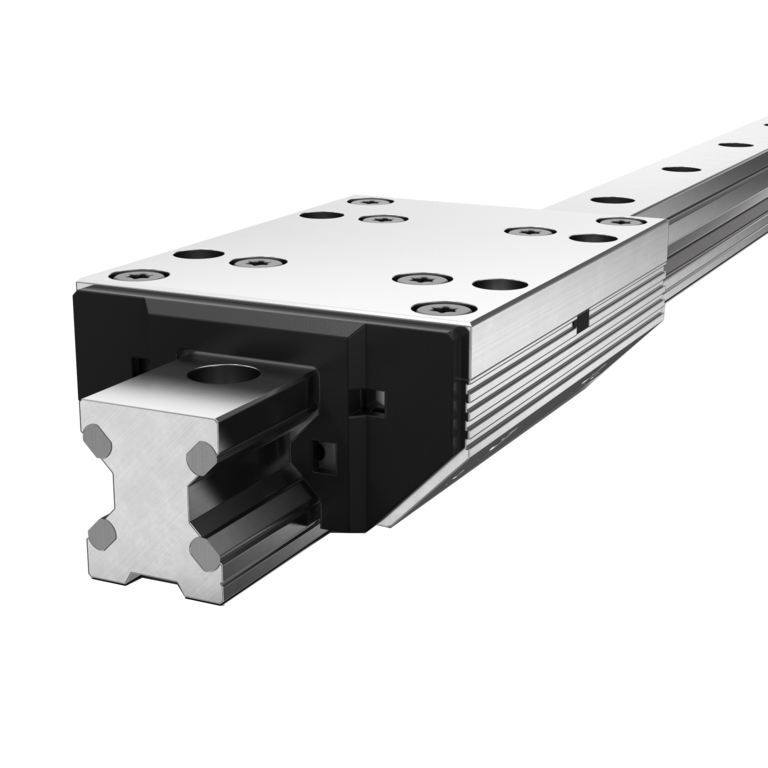

Efficient intralogistics requires components that are compact, lightweight and durable – while also ensuring maximum dynamics, precision and maintenance-free operation. Systems for internal material flow often operate continuously and under changing loads. Roller bearings and linear guides must therefore function reliably, even at high accelerations, short cycle times and limited installation space.

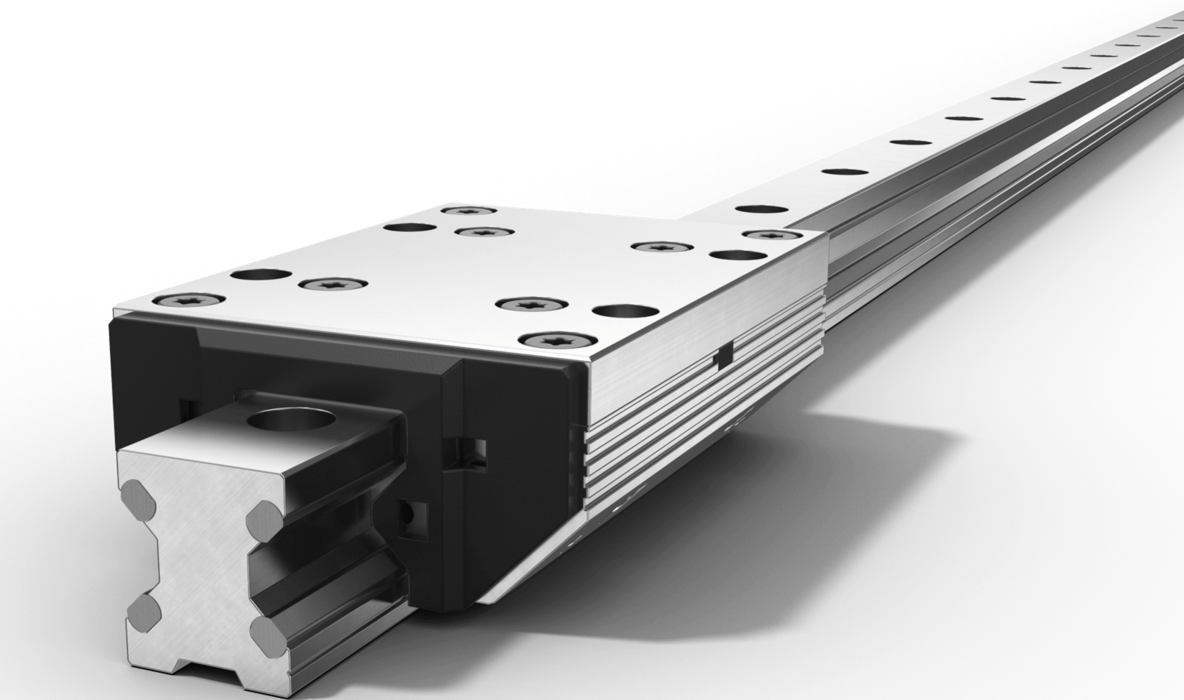

Franke wire race bearings and aluminium linear guides meet these requirements to a particular degree. They combine lightweight construction and robustness with high rigidity and adaptability – individually designed for transport, conveyor and handling systems in modern intralogistics.

Intralogistics requirements

High dynamics

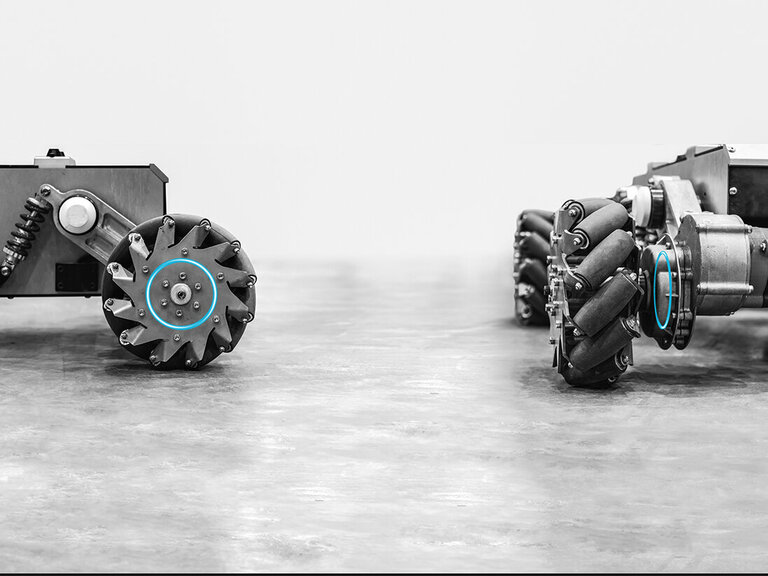

AGVs, shuttles and storage and retrieval machines move at high accelerations and short cycle times. Start-stop cycles and changes of direction require smooth-running, low-vibration components with minimal friction torque.

High load capacity

In many applications, radial, axial and tilting forces act simultaneously. Compact designs with high rigidity ensure the required precision even with eccentric loads and tight installation spaces.

Challenging environments

Dust, moisture and temperature fluctuations are part of everyday life. Corrosion-resistant materials, enclosed raceways and lifetime-lubricated systems ensure reliable operation with minimal maintenance.

Energy efficiency

In battery-powered electric vehicles, every gram and every reduction in friction counts. Lightweight aluminium components and optimised raceways contribute directly to energy efficiency and range.

Reliable continuous operation

Intralogistics systems operate around the clock. This calls for durable, fail-safe bearing and guide solutions that deliver consistent performance throughout their entire life cycle.

Application examples

Installation space, weight, efficiency:

how you can optimise your drive units

The choice of bearing determines the performance of your drive system.

In this whitepaper, you will learn how wire roller bearings create new design possibilities and why leading manufacturers already rely on Franke.

Customer Story

Automated guided vehicles from the global production optimiser

Always thinking one step ahead and offering flexibility - that is the credo of FFT, a leading global provider of automated manufacturing solutions. To achieve this, the plant manufacturer relies on collaboration between humans and robots and on digital networking.

Products particularly relevant to intralogistics

Get to know our products better. Here you will find links to our standard designs.

If your requirements are more specific, we will be happy to work with you to find the optimal solution for your application.

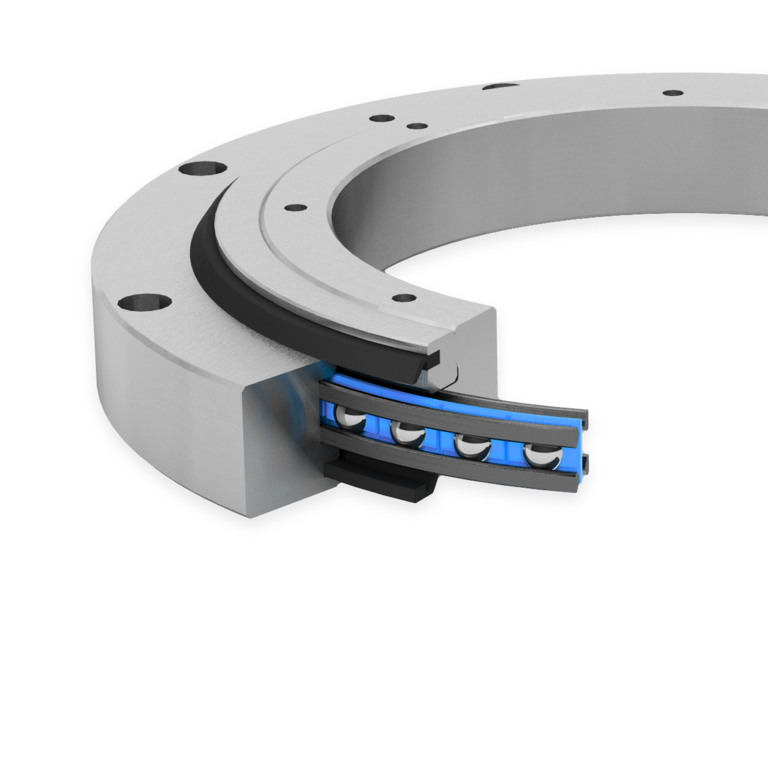

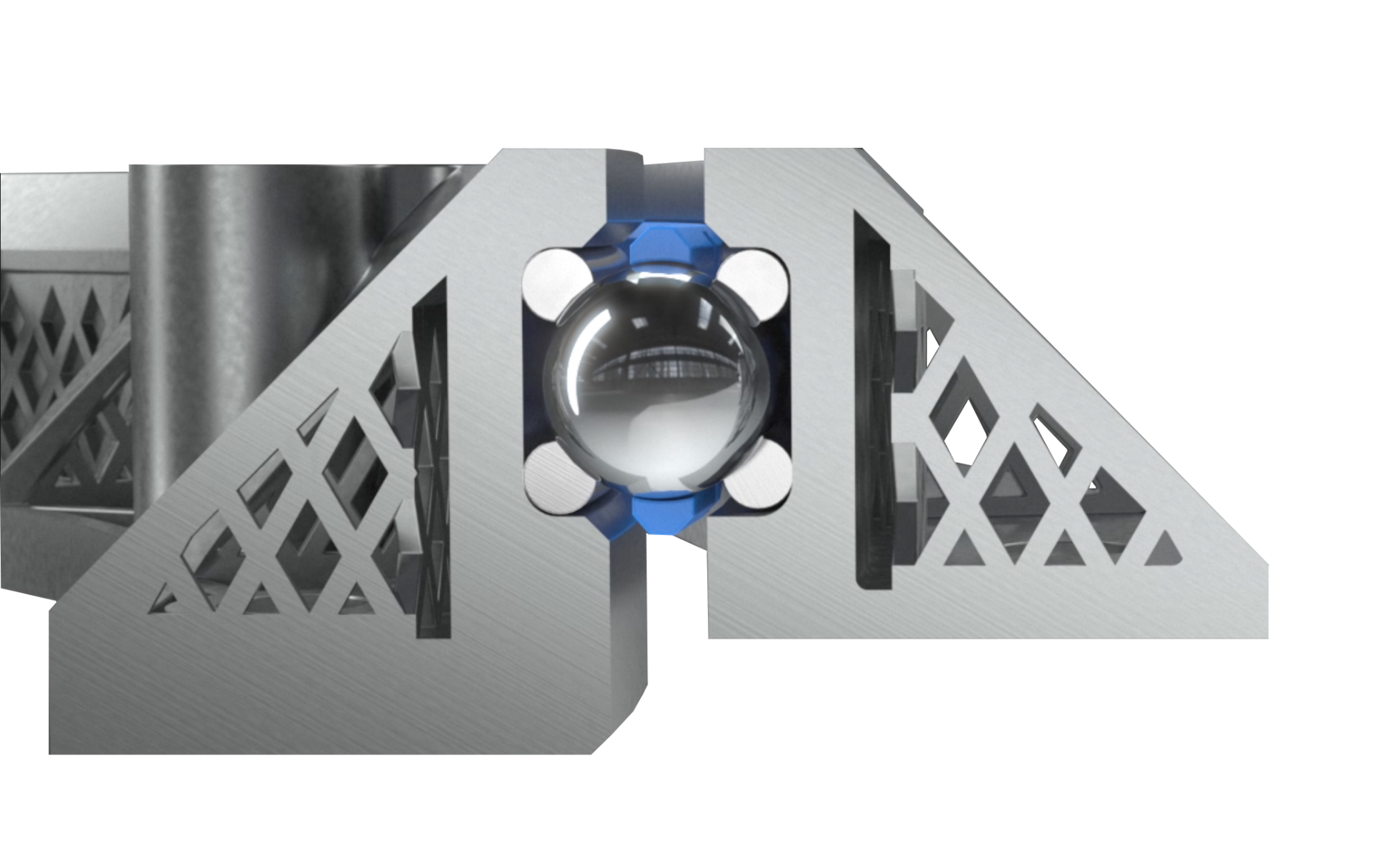

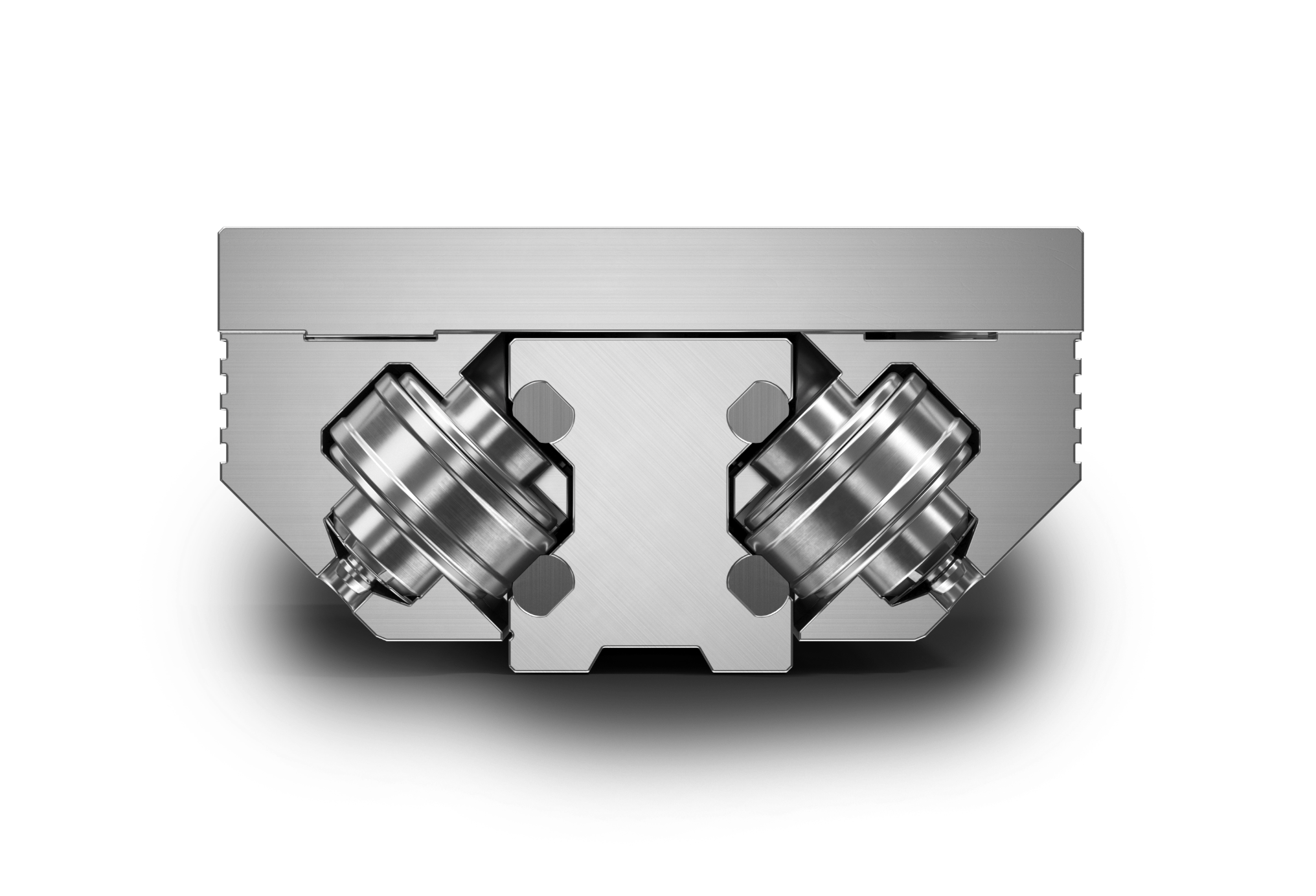

Franke roller bearings adapt thanks to modular system

The most important Franke advantage: A Franke solution can be optimally adapted to specific conditions. This is why Franke wire-race bearings and roller guides are also ideally suited for suitable for motion control in logistical transport and handling systems.

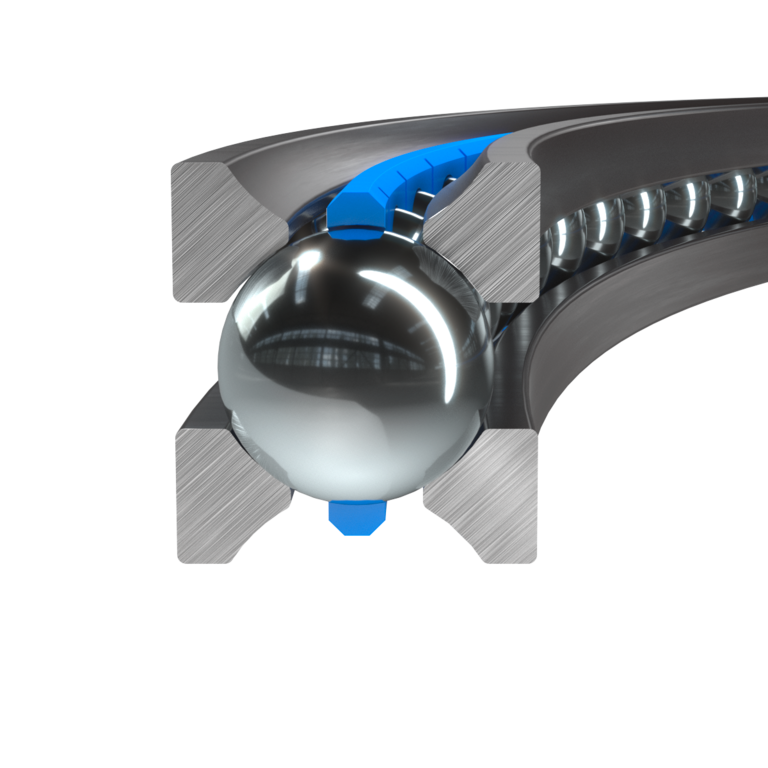

Design freedom thanks to the Franke principle

Franke roller bearings differ significantly from conventional deep groove ball bearings and linear guides in one respect: Franke roller bearings run on inserted wires. This principle allows for great design freedom and numerous benefits.

Your contact

Expert advice is the basis for a suitable solution.

I would be happy to advise you personally

Christian Burghard

Technical consultant

Tel: +49 7361 920 124