Fields of Innovation for roller bearings

With progressive ideas and concepts, we create customised solutions in the areas of lightweight construction, precision and direct drive. With minimal installation space and high load capacity, our bearings are ideal for applications that require a customised, energy-efficient and reliable design.

The large selection of materials enables flexible adaptation of the enclosing design to a wide range of conditions and requirements.

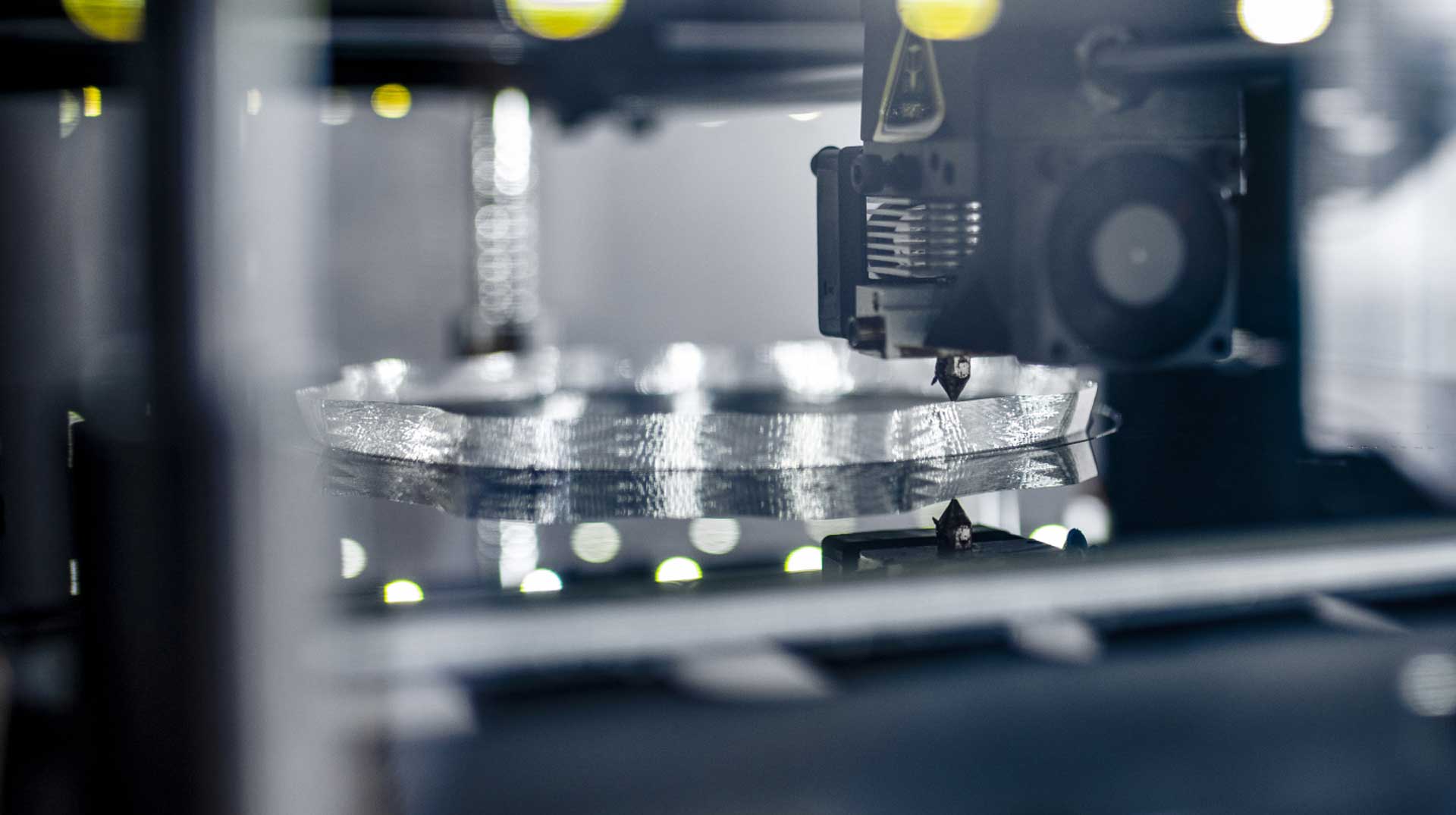

Additive manufacturing

Thanks to the ingenious 4-point technology, wire roller bearings are particularly well suited for integration into additively manufactured housings. They do not require complex machined raceways in the housing itself.

Hollow structures allow for complex and weight-optimised housings or functional integrations that would not be possible with conventional manufacturing methods. In addition, there is a wide variety of materials to choose from to meet the requirements of the application. This makes 3D printing the ultimate lightweight option beyond high-strength aluminium slewing rings.

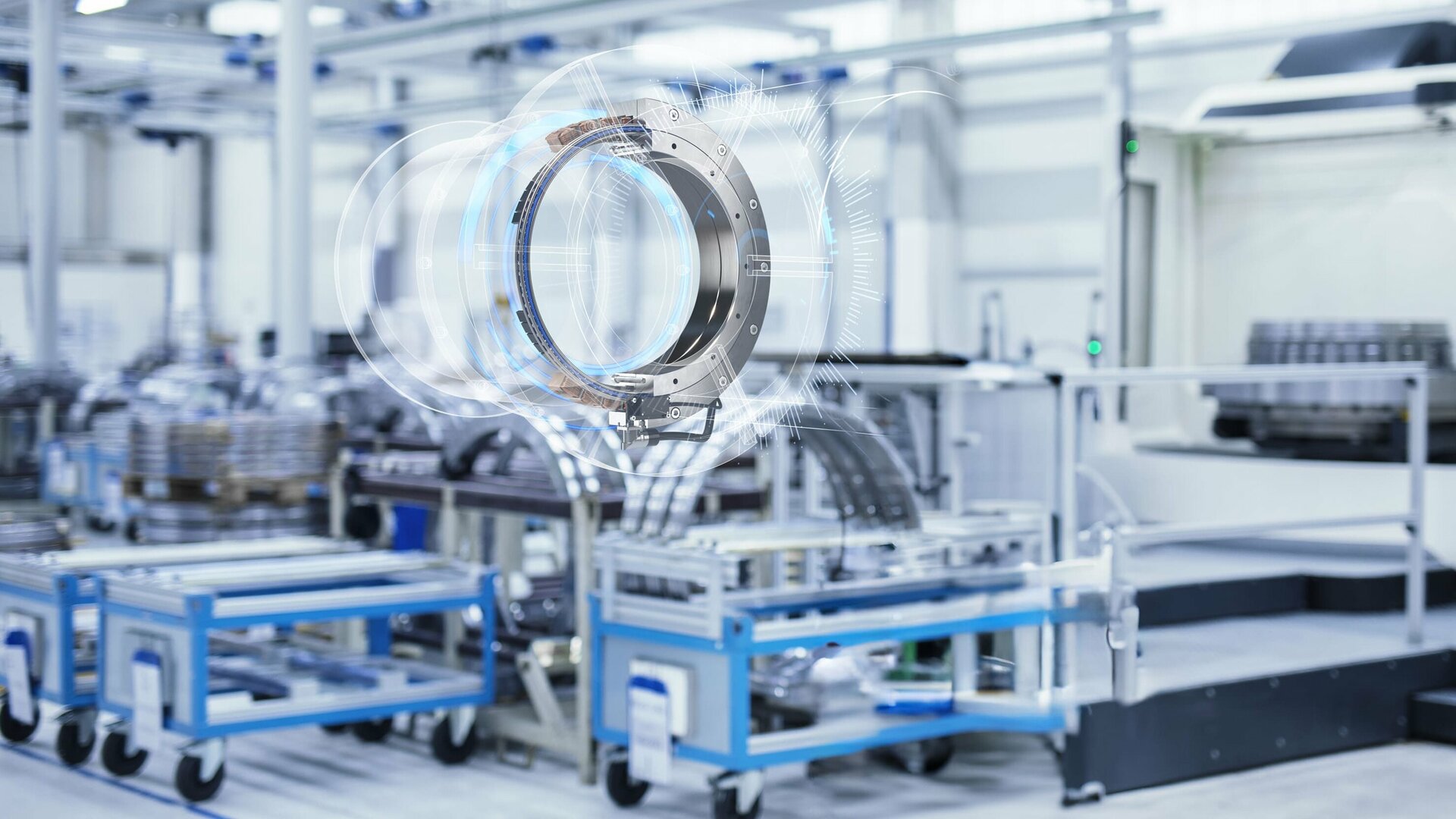

Slewing ring with torque

Slewing rings with integrated direct drive (torque) offer maximum energy efficiency and enable a compact, space-saving design. By dispensing with additional components such as gears and drive pinions, power losses due to friction or play are significantly reduced, which considerably minimises maintenance costs.

The above-mentioned advantages and the precision of the direct drive fulfil a wide range of requirements. This technology is preferably used in medical technology in computer tomographs, in mechanical engineering or in measuring and testing technology.

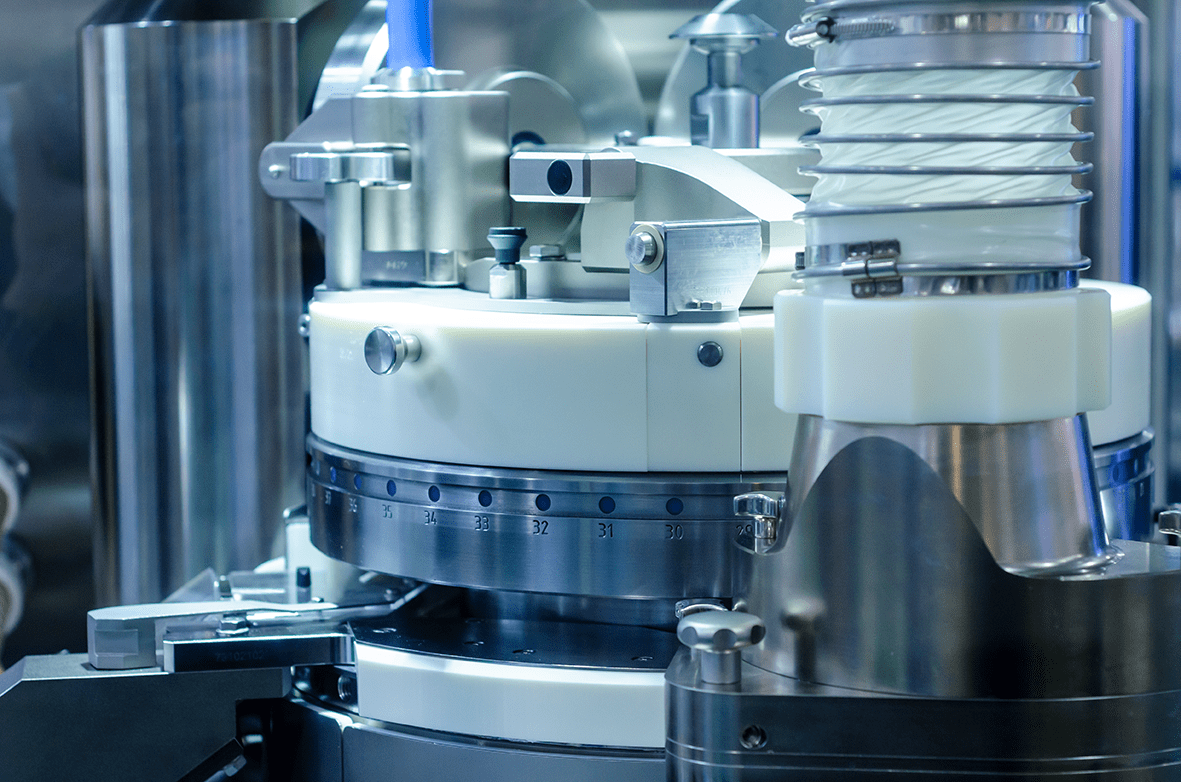

Materials for bearings

Which materials are suitable for rolling bearings in challenging, sensitive or extreme applications? This section provides an overview of the possible uses of alternative materials for the housing of a slewing ring, such as non-magnetic steels, CFRP, aluminium or plastic.

Application examples from conveyor technology, food technology, lightweight construction and aerospace show how functionality, weight and corrosion resistance can be optimised through the targeted selection of materials. Particularly relevant for anyone looking for customised solutions that go beyond the standard.

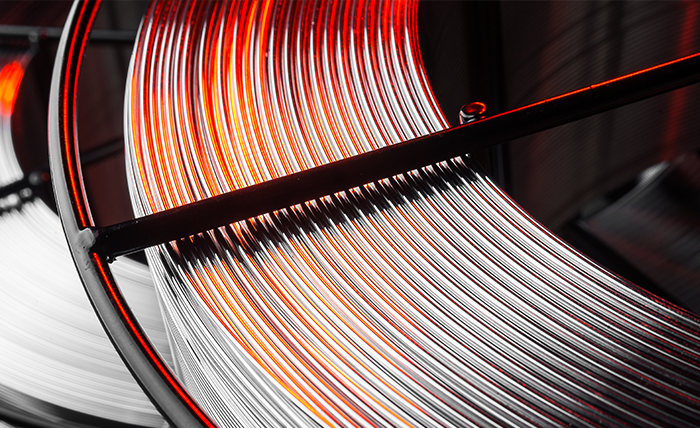

Heavy duty - high load capacity

The use of crossed roller bearings in combination with hardened races enables slewing rings to be realised for the highest loads. A new machining method used in the manufacture of the running wires ensures the realisation of extremely high rigidity and load ratings, even with smaller diameters from 300 mm.

Slewing rings with crossed roller bearings and raceways made of hardened wire are suitable for applications with the above-mentioned requirements, compact installation space and high torque loads.